Customer Service

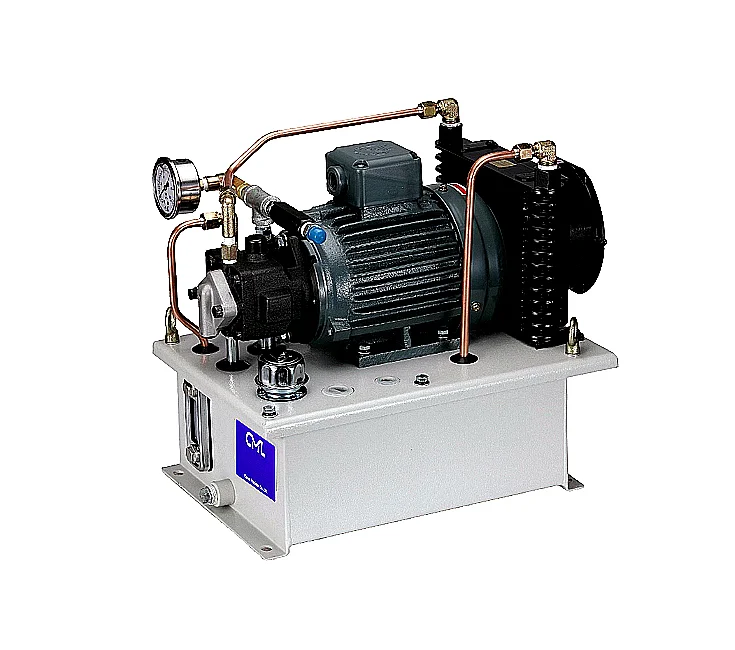

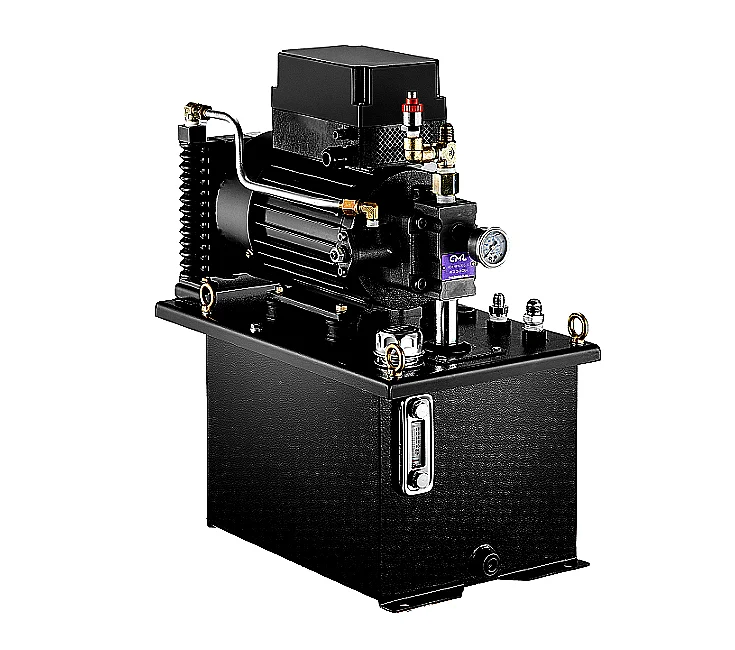

Leveraging nearly 45 years of deep involvement in the machinery industry, CML offers robust manufacturing and assembly capabilities for over 500 products across 8 major categories, establishing a solid technical foundation for customized solutions.

This extensive technical background and integration experience enable CML to collaborate deeply with clients. We focus on specific application needs, usage scenarios, and on-site working conditions to develop integrated solutions optimized for actual conditions.

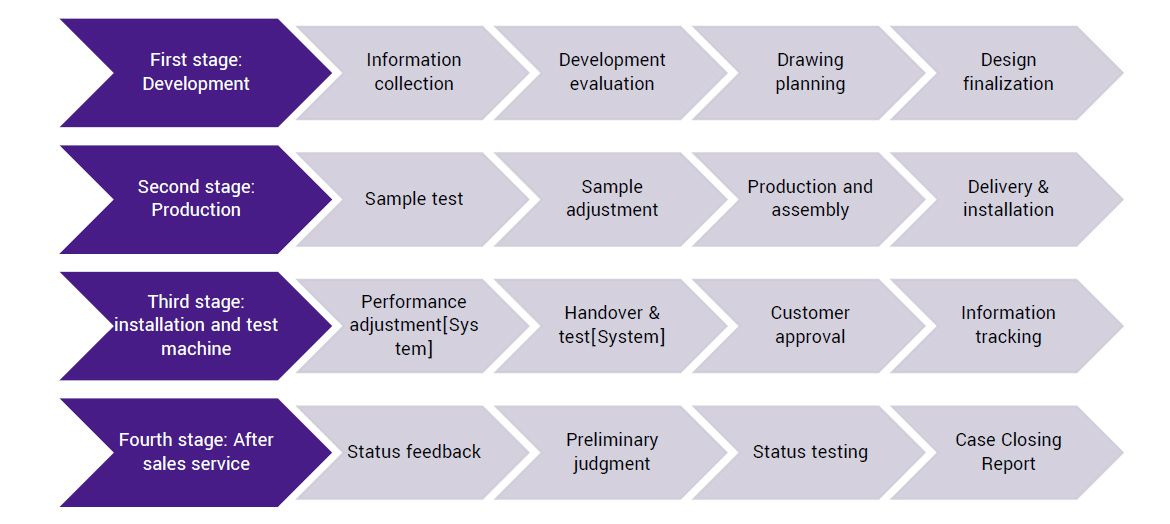

First Stage: Development

After effective communication between CML professional team and the client to understand their needs and requirements, a multi-faceted evaluation is conducted, and preliminary suggestions are provided. Next, during the planning stage, close discussions are maintained to ensure the design is stable and closely aligned with the site conditions. In the design stage, it is confirmed that the system specifications and hydraulic circuit fully comply with the application requirements, delivering on the promise of accurate and appropriate operation.

Information Collection:

Thoroughly understand the client's equipment operating conditions, production line environment, usage constraints, and application requirements.

Development Evaluation:

Based on the collected information, discuss specification feasibility, technical compatibility, and cost-effectiveness, then present a preliminary solution.

Drawing Planning:

Once the customer confirms required specifications and estimated costs, we proceed with drawing and solution discussions, designing a plan closely aligned with the usage scenario to ensure stable operation under the customer's required conditions.

Design Finalization:

After close consultation, verify that the system design's circuits and specifications meet the application's working condition settings.

Second Stage: Production

During the manufacturing stage, based on sample test results and feedback, appropriate adjustments are made to the functionality to ensure stable performance after mass production. When the product is finalized, acceptance standards and bulk packaging methods for shipped products are established with the customer to prevent damage during the shipping process.Sample Test:

The sample undergoes testing under actual operating conditions to ensure optimal effectiveness and stability.

Sample Adjustment:

We implement necessary adjustments based on comprehensive test results to optimally meet application requirements.

Production & Assembly:

Mass production and assembly are carried out through standardized processes and established quality acceptance standards.

Delivery & Installation:

Suitable protection methods are used to keep the product in good condition during transportation, facilitating smooth on-site installation and positioning upon arrival.

Third Stage: Installation & Test

CML provides installation instructions and setup suggestions. When the product arrives at the customer's site and is installed (or connected to the machine's hydraulic circuit), we check the running status and values, performing detailed adjustments. After confirming normal operation, we receive the customer's confirmation of receipt, followed by satisfaction tracking and collecting feedback.

Test & Adjustment:

Complete the on-site installation of system equipment and make necessary adjustments according to the specific case requirements, site load, operational movements, and environmental conditions.

Handover Training:

Operation settings, maintenance methods, and precautions are provided to assist users in quickly getting started.

Customer Acceptance:

Verify performance and operation against each item to guarantee stable equipment function.

Feedback Tracking:

Collect initial usage status and feedback to continually assist customers with optimization.

Fourth Stage: After-Sales Service

CML highly values every piece of feedback. To help customers maintain stable in long-term operations, CML offers fast, flexible after-sales support. Through continuous improvement, we ensure the customer's machinery maintains superior market competitiveness.

Status Feedback:

Customers can report usage situations through various ways, allowing us to promptly stay informed.

Preliminary Assessment:

The professional team will analyze the situation based on the reported information and propose immediate technical solutions to minimize downtime.

Status Inspection:

If the customer cannot directly resolve the issue, we will assess and arrange on-site inspection based on product category, situation characteristics, and location, or request the customer to send the product back for inspection to improve processing efficiency.

Final Report:

We will issue a report explaining the cause, the handling methods, recommending subsequent solutions, and will archive the customer's feedback.

Customer Service | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate