How to Install G02 & G03 Solenoid Valves (ISO, DIN Connection Type)

In the field of industrial hydraulic power transmission, solenoid valves serve as the critical intelligence behind automated control. Since hydraulic systems operate under constant high pressure and high-frequency cycling, even the slightest installation error—such as O-ring displacement or uneven bolt torque—can result in internal leakage, pressure drop, or catastrophic system failure.

Below is a quick guide to the installation steps. For a more detailed tutorial, please watch the video below.

CML G02 Solenoid Valve Installation Guide

- Inspect appearance and verify hex bolt quantity.

- Verify that the model and coil voltage (AC/DC) match the technical drawing.

- Confirm hex bolt dimensions and length.

- Identify Port A and Port B positions (refer to the video for identification methods).

- Inspect O-rings for looseness or uneven seating.

- Align with the manifold and mount the solenoid valve.

- Use a hex key to pre-tighten bolts in a diagonal sequence.

- Use a torque wrench for final diagonal tightening.

CML G03 Solenoid Valve Installation Guide

- Inspect appearance and verify hex bolt quantity.

- Verify that the model and coil voltage (AC/DC) match the technical drawing.

- Confirm hex bolt dimensions and length.

- Inspect O-rings for looseness or uneven seating.

- Align with the manifold and mount the solenoid valve.

- Use a hex key to pre-tighten bolts in a diagonal sequence.

- Use a torque wrench for final diagonal tightening.

CML Solenoid Valve Wiring Guide: ISO Terminal Box Type

- Remove the nameplate and crimp Y-terminals onto the wires.

- Thread the wires into the terminal box.

- Connect the wires according to requirements (the terminal with the copper plate is the common point; only one connection is needed).

- Fasten the nameplate.

- Tighten the cable gland.

CML Solenoid Valve Wiring Guide: DIN Connector Type

- Loosen the connector screw and unplug the connector.

- Connect the wires according to requirements.

- Tighten the connector screw.

Following these steps ensures a fast and effective installation, guaranteeing proper adjustment and smooth operation of your solenoid valve.

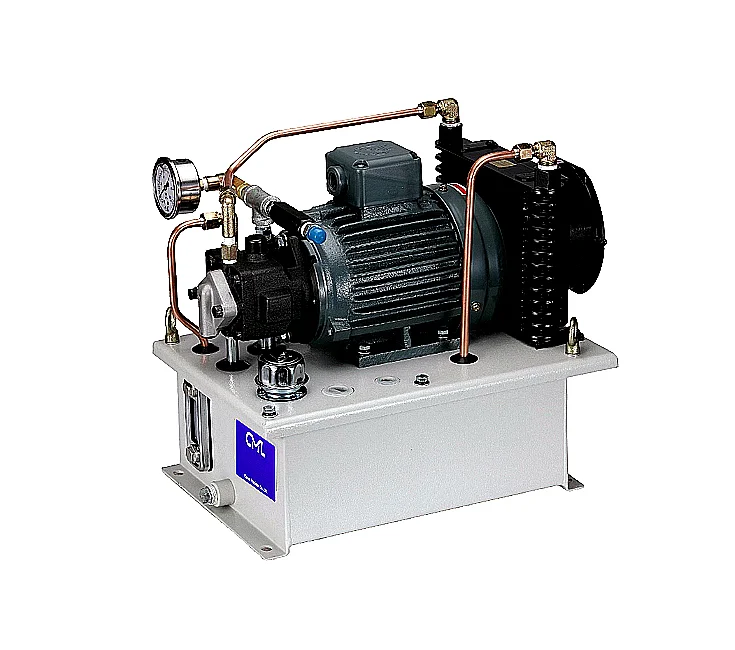

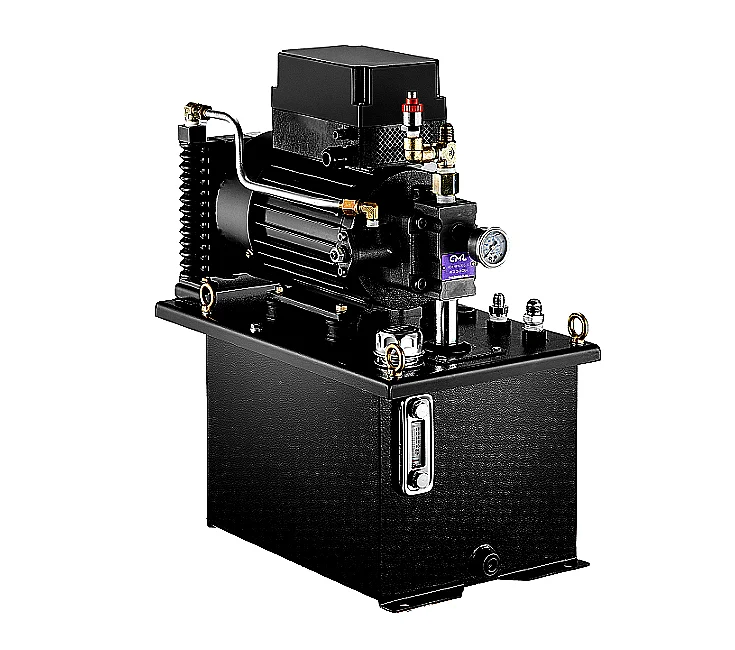

- Related Products

How to Install G02 & G03 Solenoid Valves (ISO, DIN Connection Type) | CML: ISO 9001 & CE Certified Hydraulic Pump Manufacturer – Award-Winning Quality

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate