ESG Energy-saving Hybrid Solution

Save Energy, Boost Efficiency, Drive Sustainability

CML ESG Energy-saving Hybrid Solution is designed to maximize energy efficiency and stable oil temperature. By leveraging hybrid inverter technology with IE3 (Premium Efficiency) motors, the system reduces motor speed during continuous pressure-holding, saving 40–60% in power consumption while lowering operating noise to enhance the working environment. Its superior oil temperature control effectively minimizes heat generation, improves machining accuracy, saves installation space, and reduces hydraulic oil usage—making it the ideal upgrade for energy savings, environmental sustainability, and operational efficiency. This commitment to performance and sustainability has earned the solution the distinction of Winner of the 2025 EEA Energy Efficiency Award.

Why Choose CML ESG Energy-saving Hybrid Solution?

Choosing the CML ESG Energy-saving Hybrid Solution is a high-efficiency strategy for enterprises to transition toward green manufacturing while resolving core operational pain points. Financially, in the face of rising energy costs, this system delivers a significant 40%–60% reduction in electricity expenses, ensuring a rapid return on investment (ROI). Furthermore, its low oil-temperature characteristics effectively extend equipment lifespan, directly converting former operating overhead into increased profit margins.

Regarding market competitiveness, CML empowers customers to align seamlessly with international carbon reduction regulations and carbon fee challenges. By providing precise, data-driven energy-saving proof, we help our clients secure a decisive edge in winning sustainable global contracts. On the production line, the upgrade process is exceptionally efficient, allowing for transformation without prolonged downtime, while the system's low-noise operation drastically improves the workplace environment. Ultimately, this is more than a technical upgrade—it is a core strategy for fulfilling ESG commitments, strengthening brand value, and building long-term market resilience.

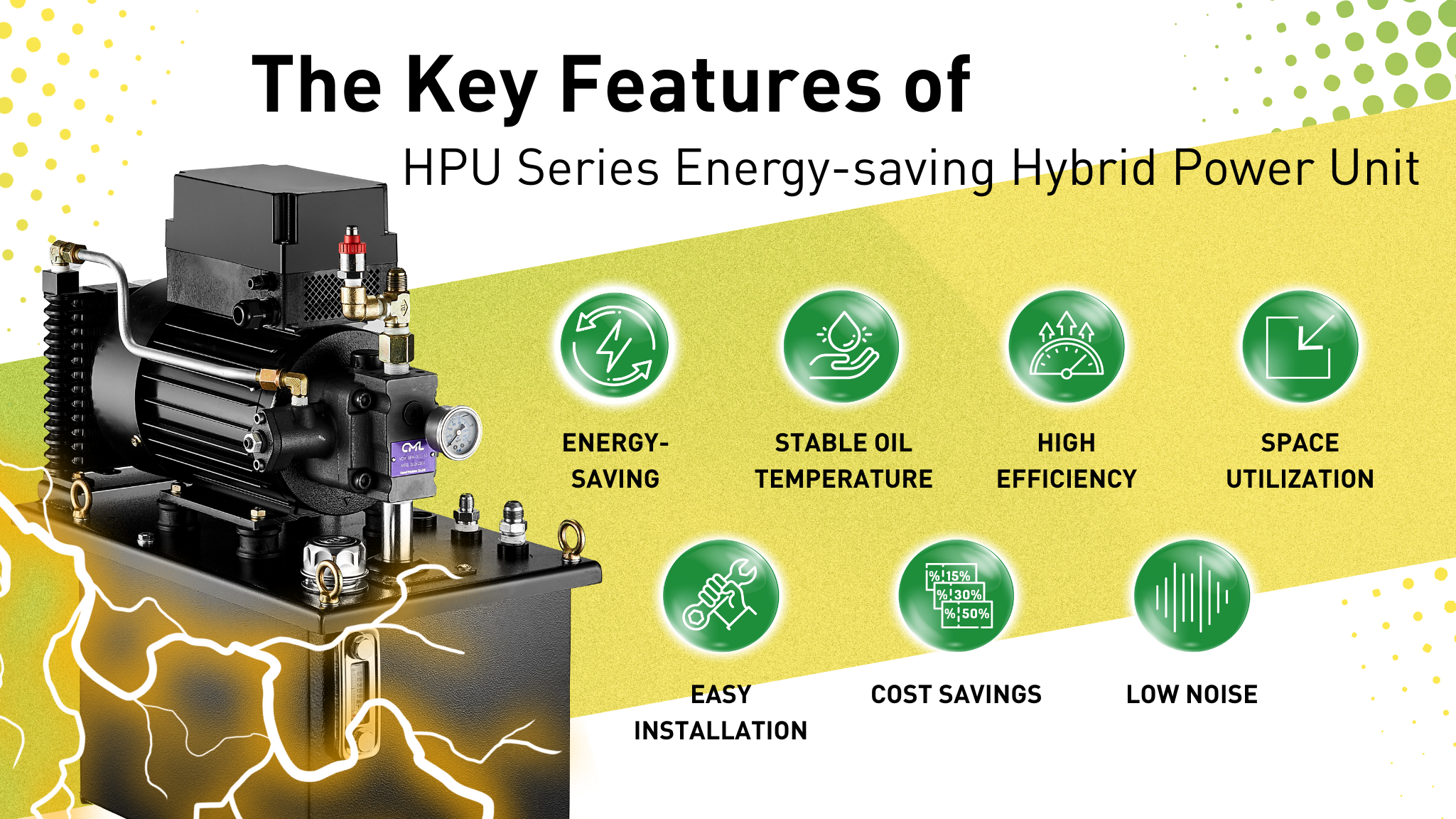

Key Features of CML ESG Energy-saving Hybrid Power Solution

1. High Energy Savings:

Cuts electricity usage by 40–60% with advanced hybrid inverter control.

2. Stable Oil Temperature:

Keeps the oil temperature within 2.5°C of ambient temperature.

3. High Efficiency:

Provides 100% stable pressure even at low speeds.

4. Space Utilization:

Reduces tank size by 40-60%.

5. Easy Retrofit:

Upgrades existing machines without replacing the entire system, and is ready to use by simply connecting the motor power line.

6. Cost Savings:

Reduces the specification requirements for cooling systems, saves oil and electricity.

7. Lower Noise:

Reduces operating noise by about 6 dB for a quieter workplace.

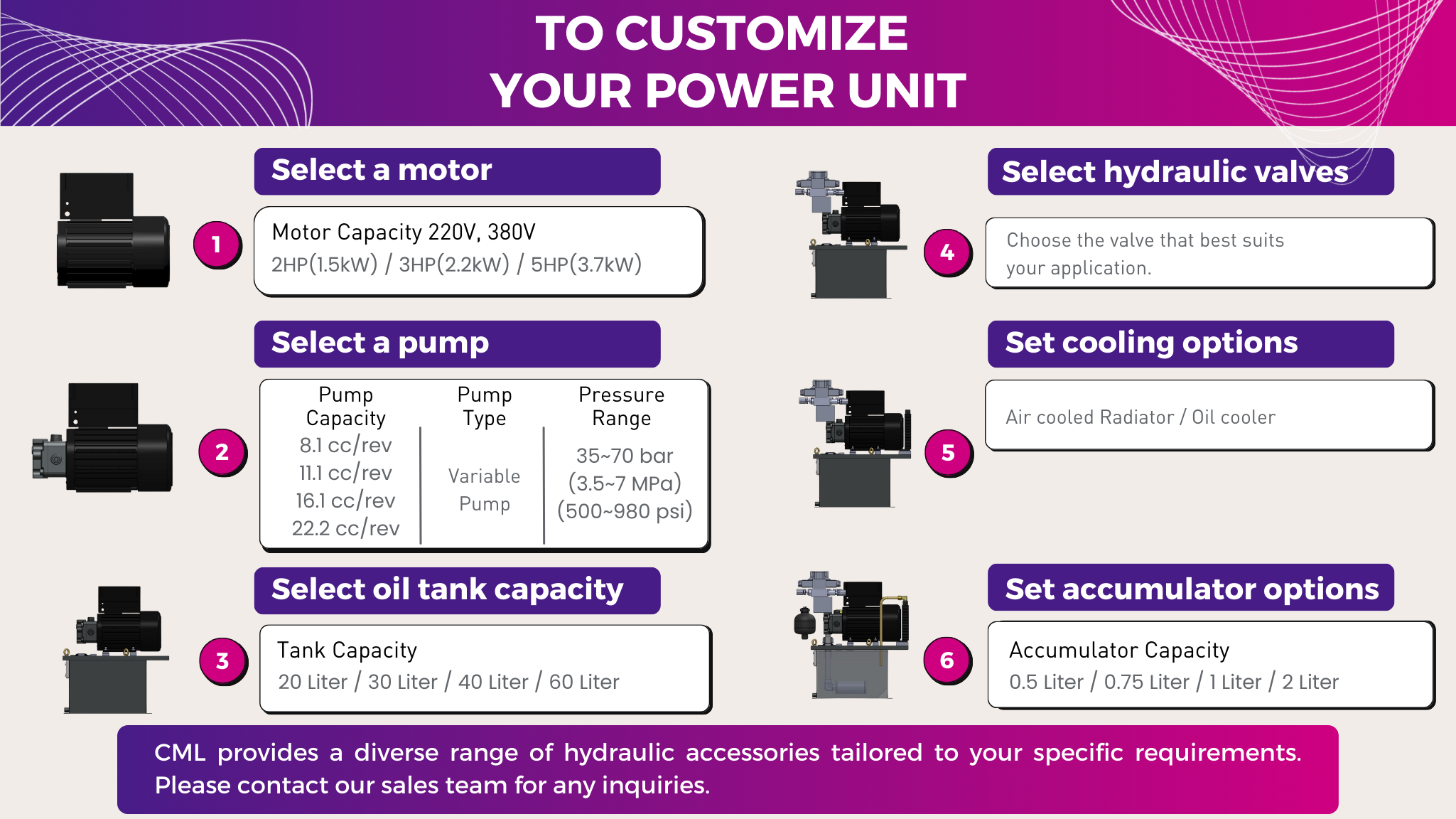

Flexible Integration with Customized Hydraulic Power Units

CML modular selection process empowers you to customize the ideal ESG energy-saving system. Start by choosing a motor (up to 5HP, 220V/380V) paired with a variable displacement pump (8.1 to 22.2 cc/rev, up to 70 bar). We offer tank capacities from 20 to 60 liters and optional specific hydraulic valves to meet your functional requirements. To ensure peak performance, you can add air or water coolers for temperature stability and accumulators up to 2L for pressure regulation. While this modular framework provides a clear starting point, our professional team is ready to evaluate your specific needs and engineer a tailor-made energy-saving solution for you.

With selection process, customers can first understand the basic principles of matching an ESG energy-saving hybrid power hydraulic system. After further consultation, our team evaluates the actual requirements and provides a tailored solution for maximum efficiency and savings.

CML Is Here to Solve Your Toughest Challenges

- Does your machine require long hours of pressure holding?

- Is it often running at low load with long idle times?

Amid the trend of energy saving and carbon reduction, the operating characteristics of your machines play a key role in successful upgrades. For equipment that runs under long pressure holding time, low-load, or standby conditions, the limitations of traditional hydraulic systems become even more apparent, and CML ESG Energy-Saving Hybrid Power Solution is designed to solve exactly these challenges.

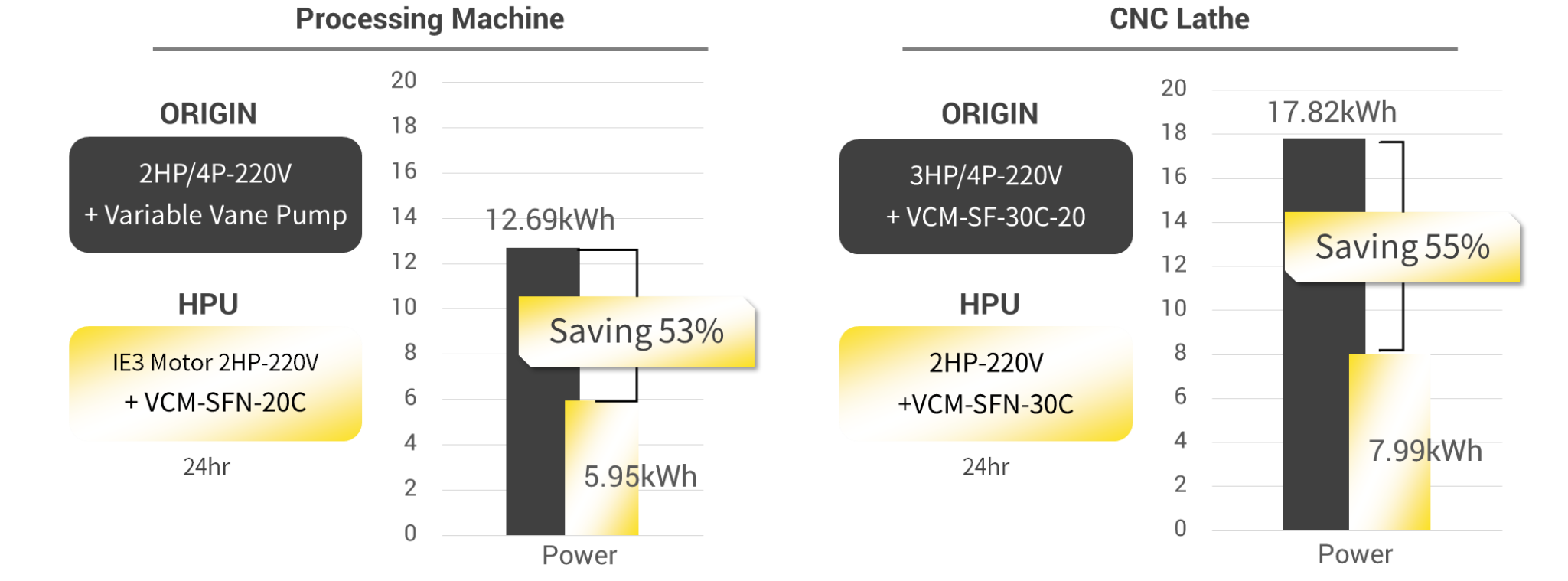

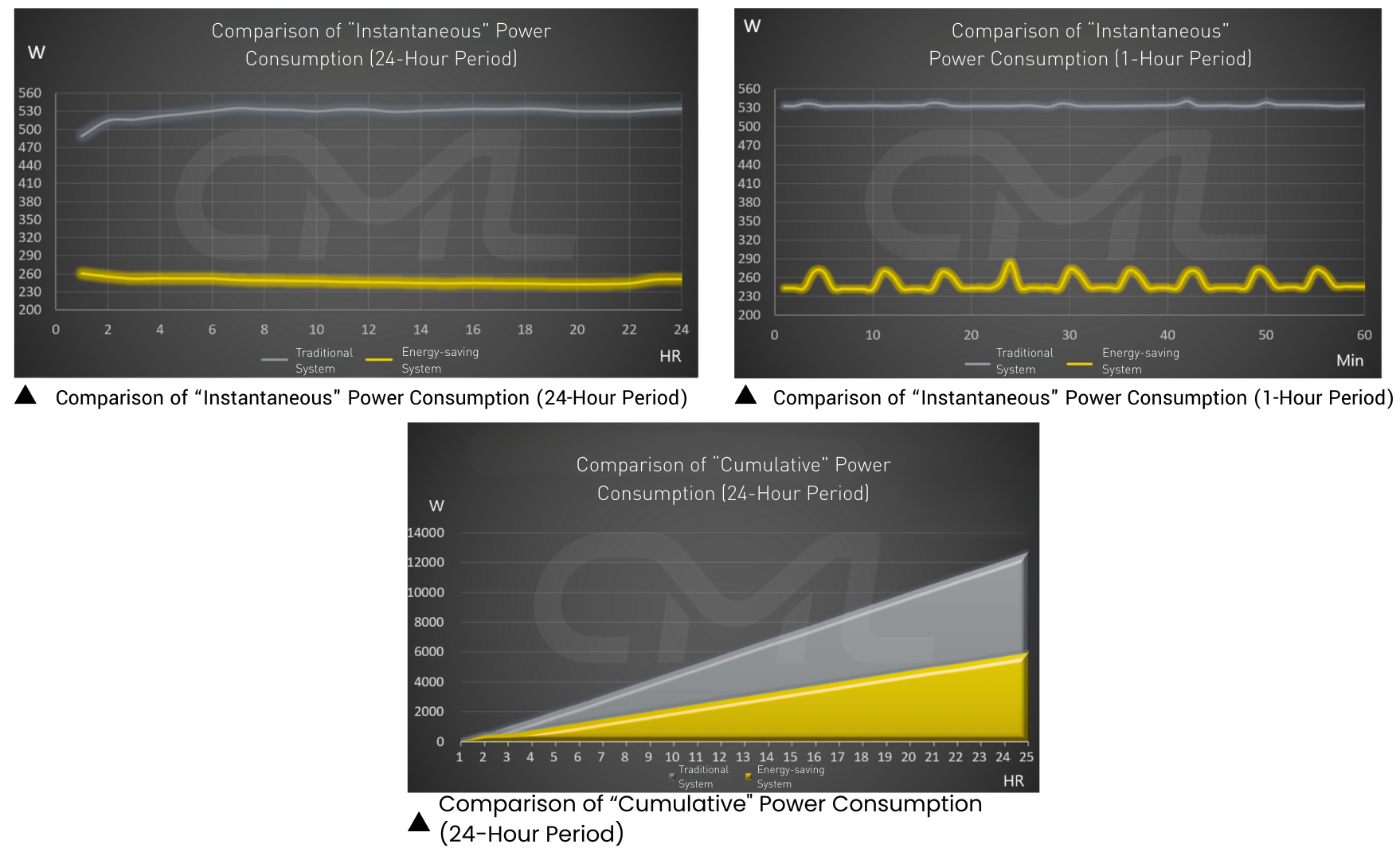

The Proof of Saving 50%

See how a traditional hydraulic system compares to an Energy-saving Power Hybrid system during operations under long pressure holding time.

Based on CML team’s evaluation, traditional hydraulic systems upgraded with hybrid inverter technology, high-efficiency IE3 motors, and properly matched pumps can achieve power savings of 45% on vertical machining centers and 55% on CNC lathes. The longer the machine has been in use, the greater the benefits from retrofitting.。

If you’re unsure whether your equipment is suitable for an upgrade, here are 3 key factors to consider:

- Machines with long standby or pressure holding time

- High concern for temperature rise, noise, and energy efficiency

- Older machining equipment

Contact us for a professional evaluation with our expert team. We will provide the solution-oriented upgrade recommendations and design a customized solution to maximize efficiency for your specific machines.

Customer Success Story

Here is a successful example with a vertical machining center. CML team evaluated the actual machining operations and machine usage, then designed a retrofit plan to upgrade the traditional hydraulic system. The system was equipped with high-efficiency IE3 motors with hybrid inverter technology and paired with a properly matched variable vane pump.

Using precision monitoring instruments (HIOKI power meter), we measured both instantaneous and cumulative power consumption. The upgraded system achieved approximately 53% energy savings, while maintaining stable oil temperature. This retrofit delivers multiple benefits: energy savings, reduced power consumption, and improved machining stability.

Hydraulic Applications in Vertical Machining Centers

- Tool Clamping System – Clamping and releasing unit

- Tool Changer – Arm rotation/movement and tool exchange

- Fixture Clamping – Holding workpieces securely in place

- Worktable – Rotation, positioning, and locking

Machine Testing Conditions & Configuration Comparison

Evaluation of system performance under real operating conditions and comparison of different setups

| Test Condition | Motor Specification | Motor Speed rpm/min | Pump Type | Max Pressure bar | Total Pump Flow L/min | Measurement Time |

|---|---|---|---|---|---|---|

| Traditional Hydraulic System | 2HP/4P-220V | 1720 | Variable Vane Pump | 39 | 20 | 24 hr |

| Energy-saving Power Hybrid System | IE3 Motor 2HP/220V | 400–2000 | CML Variable Vane Pump |

Benefits of the ESG Hybrid Inverter Solution

- Significant Energy Savings – By adjusting motor speed based on actual demand, the system eliminates unnecessary standby time and reduces electricity costs by up to 53%.

- Extended Equipment Life – Controlled motor speed prevents continuous high-speed operation, keeping oil temperature stable. This helps extend the service life of hydraulic oil, seals, and other key components while reducing maintenance frequency and repair costs.

- Lower Noise Levels – Reduced motor run-time minimizes noise in the workplace, creating a quieter and more comfortable production environment.

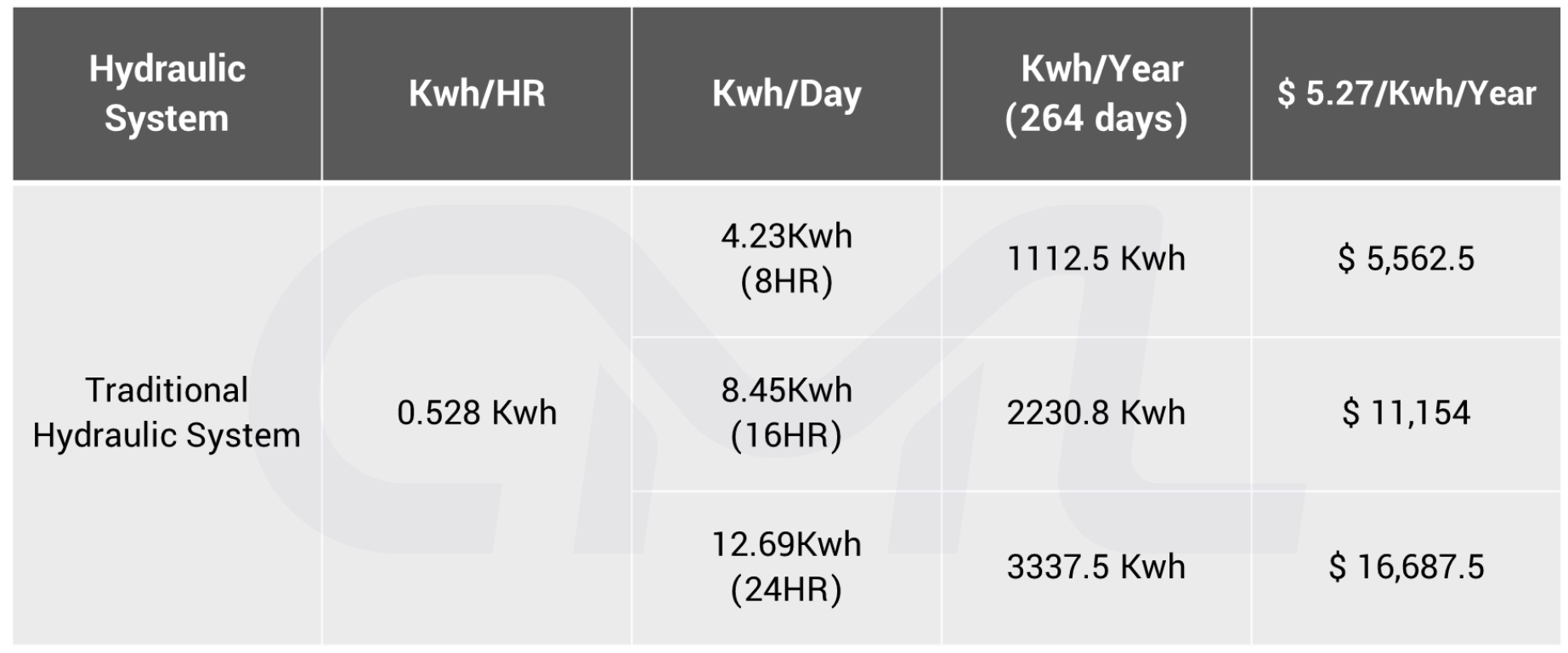

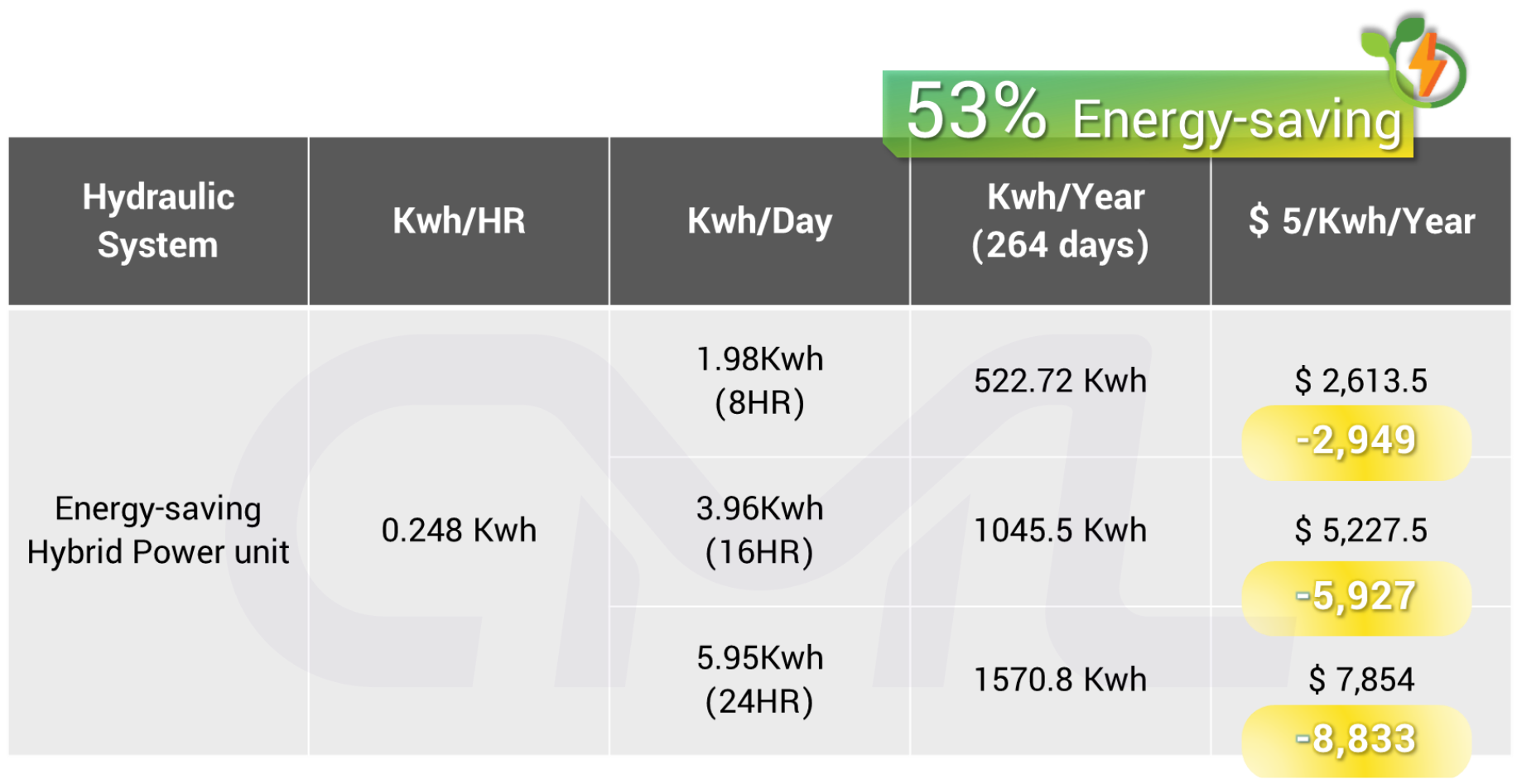

Energy & Cost Savings: Before vs. After Implementation

After measurement, a traditional hydraulic system consumes 0.528 kWh per hour, totaling 12.69 kWh for 24-hour daily operation, which translates to an annual electricity cost of NT$16,687.

Energy-saving hybrid power system reduces power consumption to 0.248 kWh per hour, saving 53% energy. The annual electricity cost drops to NT$7,854, resulting in NT$8,833 in savings.

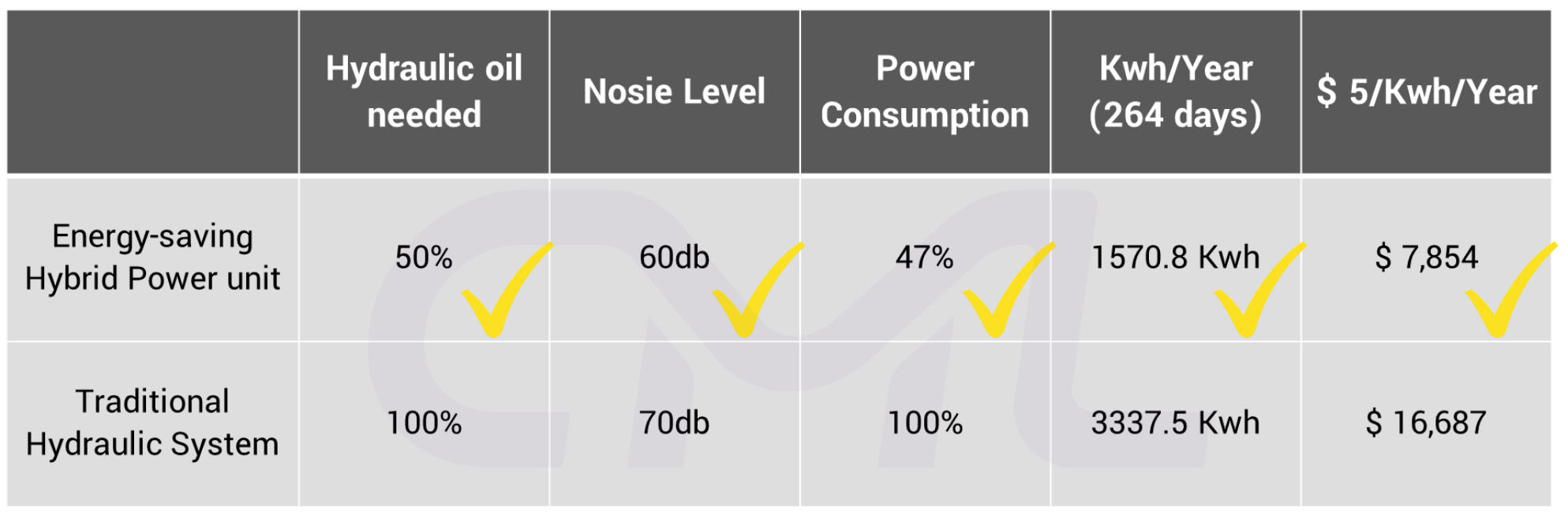

In terms of hydraulic oil consumption, noise level, power consumption, and operating costs, the energy-saving system significantly outperforms traditional systems.

Based on the power and cumulative consumption curves, energy-saving hybrid power system consistently maintains power usage at around 50% of that of traditional systems.

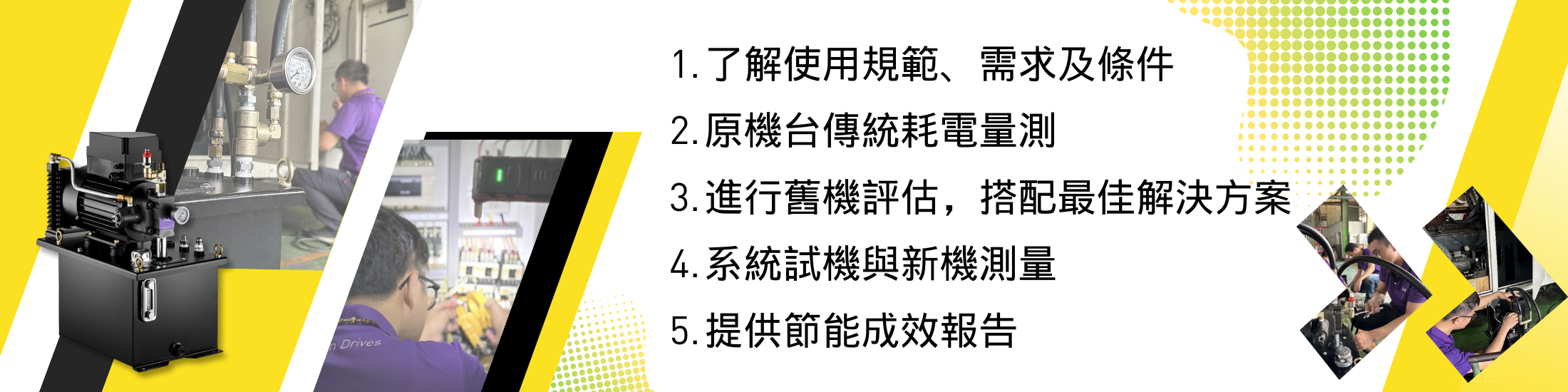

Tailored Retrofit Services | Clear Energy-Saving Results at a Glance

CML provides a comprehensive energy-saving retrofit service, designed to help manufacturers reduce costs and improve performance. Our process includes five clear steps:

- On-site evaluation – We assess machine operation, production workflow, and customer requirements.

- Measurement – Using professional tools (HIOKI power meter), we record the actual power consumption of existing machines.

- System design – Our experienced team recommends the best motor and pump combination for maximum efficiency.

- Testing & validation – We run trial operations and measure the new system’s performance.

- Power Consumption report – Customers receive a detailed performance report with data charts for easy comparison.

With this structured approach, CML helps customers evaluate ROI with real data, while achieving both energy savings and improved machine performance.

Why It Matters?

Global manufacturing is moving toward sustainability and carbon reduction. From the International Energy Agency (IEA) forecasts to government policies, the message is clear: manufacturers must adopt energy-efficient solutions to stay competitive.

Key Benefits of CML ESG Energy-Saving Hybrid Solution:

- 40–60% reduction in power consumption

- Lower system noise by approx. 6 dB

- Better oil temperature control, extending machine and component life

- Reduced hydraulic oil usage, lowering both carbon footprint and material waste

- Improved machining stability for consistent product quality

- Ideal for machines requiring long pressure-hold times or continuous automation lines

Choosing CML’s ESG Energy-Saving Hybrid Power Solution is not just a retrofit—it’s a strategic approach to achieving ESG targets, reducing carbon emissions, and enhancing operational efficiency.

From system assessment and customized design to implementation and performance tracking, CML delivers a seamless upgrade with measurable results. It’s more than energy savings—it’s about driving sustainability and productivity together.

- Related Products

Medium & high-pressure air-cooled coolers

AH630-CA2, AH0608T-CA2, AH0608LT/RT, AH1012-CA2/3, AH1215-CA2/3, AH1418-CA2/3, AH1470-CA2/3, AH1428-ca2/3, AH1680-CA2/3

The Medium & high type coolers are suited for use on a variable vane pump hydraulic system, in which its motor is not bigger than 3HP and the system pressure...

Details

ESG Energy-saving Hybrid Solution | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate