How to install vane pump and motor

Are You Struggling with Installing Pumps and Motors?

If you find yourself struggling with the installation of pumps and motors, you're not alone. The details in the installation process are crucial, and even a small mistake can lead to significant problems. However, by following a simple yet critical series of steps, you can ensure a smooth installation process and avoid many potential issues.

First, when unpacking the pump, make sure to inspect its exterior for any abnormalities and thoroughly clean the shaft to remove any debris that could affect the installation. Next, deburr the motor connection surface and shaft hole to remove any potential burrs. This prevents scratches or damage during installation, thereby extending the lifespan of the equipment.

During installation, aligning the motor shaft hole and pump shaft is essential. This ensures smooth operation between components, reducing unnecessary wear and vibration. Additionally, tightening the bolts diagonally ensures even force distribution, securing all parts firmly in place and preventing loosening or shifting during operation.

The biggest benefit of following these steps is the significant reduction in maintenance needs due to installation errors. This means fewer unexpected shutdowns, lower maintenance costs, and longer equipment lifespan. On the other hand, neglecting these details could lead to component damage, unstable operation, reduced efficiency, and even shorten the overall system's lifespan and performance.

In summary, proper installation steps not only improve system efficiency but also extend the life of the equipment and save on maintenance costs. By doing so, you'll be able to make more effective use of your resources, avoid unnecessary troubles, and ensure that your equipment operates in optimal condition.

Quick Guide to Installing Vane Pumps and Motors

- Unpack the Pump and Check for Abnormalities

- Remove the Shrink Wrap

- Clean the Shaft

- Check that the shaft and key are intact

- Deburr the Motor Connection Surface

- Prepare for Installation

- Stand the motor upright

- Check for Smooth Operation

- Tighten Diagonally

- Remove Oil Port Cap

- Check Concentricity

By following these steps, you can quickly and effectively install vane pumps and motors, ensuring proper alignment and smooth operation.

- Files Download

How to install vane pump and motor | CML: ISO 9001 & CE Certified Hydraulic Pump Manufacturer – Award-Winning Quality

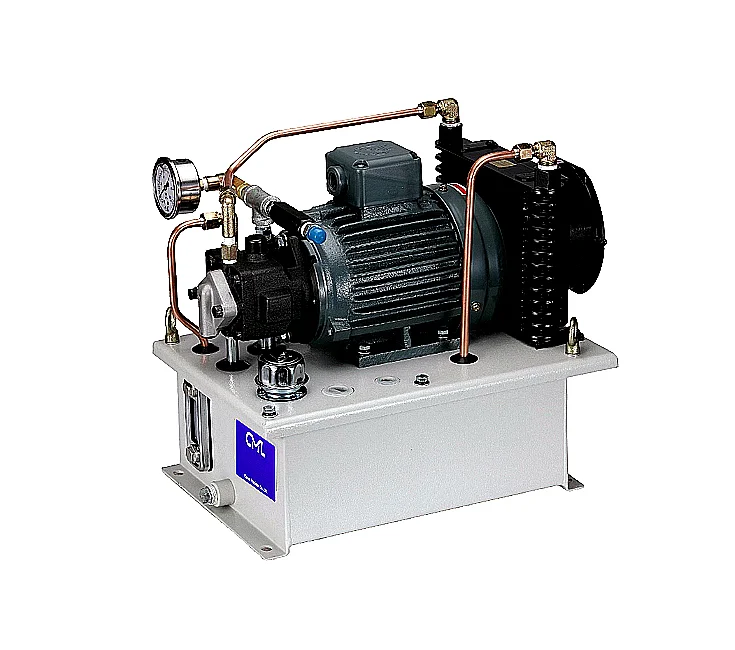

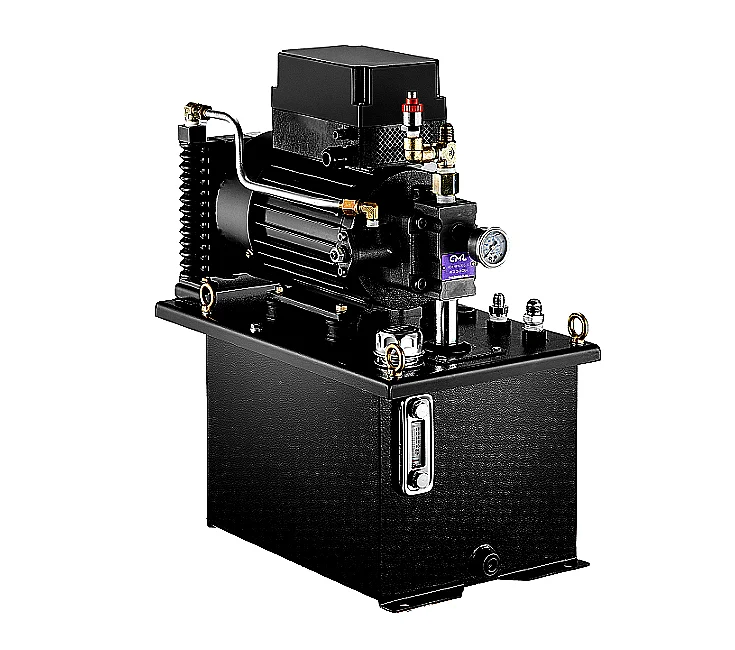

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate