ESG Injection Molding Machine Energy-saving Solution

High-stability, quick-response, and energy-efficient servo systems drive process upgrades.

Common Challenges in Injection Molding

Injection molding machines are the cornerstone of modern manufacturing, with hydraulic systems serving as both the heart and brain of the operation. However, faced with fierce market competition, stringent environmental regulations, and rising demands for precision, traditional systems are reaching their limits. CML ESG Energy-Saving Solutions empower customers to reduce energy consumption, shorten cycle times, and extend machine life through comprehensive service.

Key Challenges Facing Today’s Production Floors

Hidden Risk about product quality and process precision

Excessive pulsation:

Unstable oil pressure during injection or holding leads to inconsistent mold pressure. This results in uneven filling density and common defects like shrinkage, short shots, and dimensional errors.

Uneven low-speed operation:

Precision parts and micro-filling require extremely slow, stable flow rates to ensure consistency. Any flow interruptions or jamming at low speeds will compromise the surface quality and dimensional repeatability of the molded parts.

High oil temperature causing process variations:

Excessive heat lowers hydraulic oil viscosity, causing fluctuations in injection speed and pressure build-up time. This instability prevents operators from locking in optimal process parameters.

Why Better Efficiency Is the Best Way to Cut Energy Waste

Machine inefficiency leads to dual losses: increased energy consumption and slower response times. These factors not only drive up electricity bills but also severely impact production output, resulting in higher overall costs.

Rising electricity costs:

Traditional systems waste a lot of power during standby or pressure-holding. Because the machine keeps running at high energy even when it's not doing much work, electricity bills go up every year.

Long molding cycle:

If the system reacts slowly or doesn't have enough flow, it takes longer to inject and build up pressure. This slow speed slows down the whole production and reduces the total output.

The Growing Demand for Sustainable Business

Rising pressure from CBAM and ESG:

International companies (OEMs) are setting much stricter rules for their suppliers. They now demand better energy efficiency, lower carbon emissions, and full ESG compliance from everyone in their supply chain.

All these trends show that a good hydraulic system is the key to a machine's success. It decides your market competitiveness, production speed, and product quality. CML solution is built specifically to meet these needs.

Injection Molding Trends: The Road Ahead for Hydraulic Systems

The evolving global market for injection molding machines is demanding higher performance and greater optimization from core hydraulic systems.

These trends encompass not only efficiency and quality but also environmental responsibility. Whether it is the high flow rates required for large-scale production, the low-speed stability needed for precision parts, or the growing pressure of ESG and carbon taxes (like CBAM), all these factors are driving equipment toward higher energy efficiency.

The hydraulic system is the power center of the machine and its control capabilities are essential to meet these challenges. Every stage of injection molding, including injection and pressure compensation, relies on precise and stable hydraulic control. This precision is the main factor that determines product quality, production efficiency, and the carbon footprint.

Large-scale and simplification

Large two-platen injection molding machines are becoming very popular, especially for models with clamping forces over 700 tons. This design creates specific needs for the hydraulic system. For example, it requires high flow rates for fast mold movement and rapid pressure build-up to shorten production cycles. Additionally, the system must provide faster response times and a compact design to save space.

Hydraulic servo systems are becoming mainstream, leading to increased demand for high-precision components.

Hydraulic Servo systems have become the mainstream choice to meet increasing production demands. The main advantage of these systems is the pump's ability to follow commands quickly and accurately, which ensures energy savings and precise pressure control. This technology is essential for the growing demand for high-precision components. Products like thin-walled parts, complex structures, and automotive or electronics components all rely on the extremely stable output of these systems.

A growing awareness of green development and carbon management

Driven by the EU's CBAM carbon tax and ESG requirements, energy efficiency is no longer just an extra benefit for equipment. Instead, it has become a basic requirement for any company looking to enter international markets and global supply chains.

Technical requirements of injection molding machine for hydraulic system

As injection molding moves toward higher efficiency, every stage of the process requires precise and rapid hydraulic control. This starts with high precision and stability. The system must offer low pulsation and stable pressure to ensure consistent product quality, especially for thin-walled parts. Second, the system needs excellent adaptability. It must remain stable even at low speeds for tasks like micro-filling. Third, high responsiveness is essential to shorten molding cycles and meet the high-flow requirements of large two-platen machines. Finally, for sustainable operation, the system should offer low noise and low temperature rise. These features extend the life of hydraulic oil and components, which significantly reduces long-term maintenance costs.

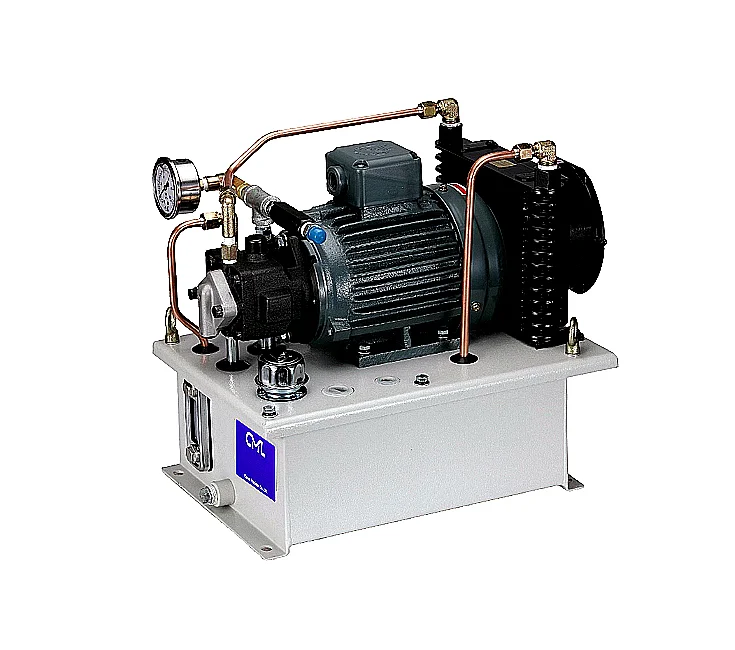

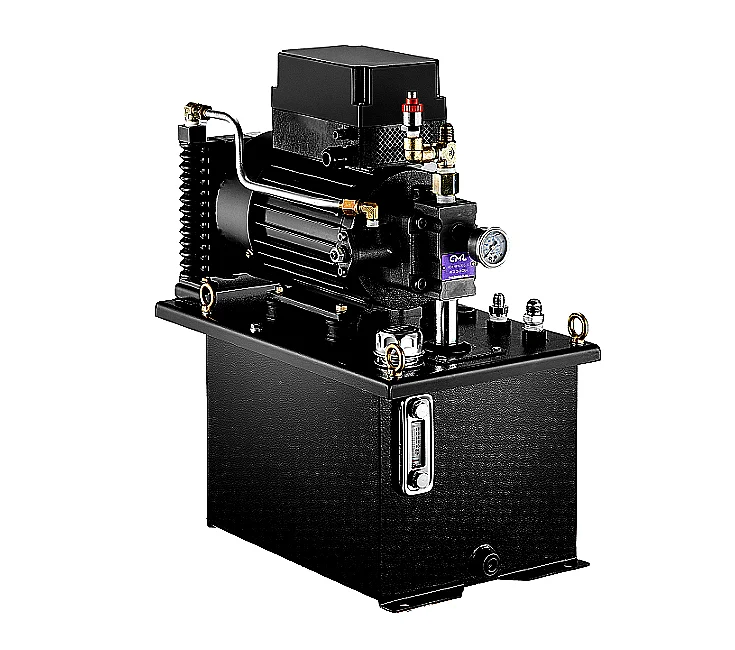

Why choose CML internal gear pumps

Internal gear pumps are standard in the injection molding industry, yet performance varies significantly depending on the brand and manufacturing process. CML combines nearly 45 years of experience in hydraulic manufacturing with advanced German technology. We offer both Taiwanese-made and German-imported internal gear pumps to provide our customers with the best options. These pumps are specifically engineered for the demanding conditions of injection molding and offer several superior features.

Higher operational stability (smoother pressure curve)

Higher operational stability (smoother pressure curve)

CML pump provides a stable hydraulic output with minimal fluctuations during the injection and holding stages. This ensures a consistent density for the melt filling, which improves both the dimensional stability and the repeatability of the finished parts.

Excellent low-speed performance and more precise injection

CML and Eckerle internal gear pumps provide a smooth and pulsation-free flow rate even at extremely low operating speeds. This consistent performance makes them ideal for manufacturing precision 3C parts and automotive components. They are also highly suitable for producing engineering plastics, thin-walled parts, and small structural components used in medical devices and high-tech industries.

Faster response speed and better performance when combined with servo control

Equipped with servo motor control, the system features a rapid response that allows it to adjust quickly and accurately to load changes. This precision is maintained during the injection, holding, and pressure replenishment stages. As a result, the machine achieves smooth speed switching and precise positioning, which effectively shortens the molding cycle and improves overall production efficiency.

Complete standardized implementation process and service advantages

CML's core advantages come from both superior product performance and our mature service processes. We understand that introducing a new hydraulic system is a vital step for clients to remain competitive. Therefore, we offer a standardized implementation process to ensure every upgrade is smooth and efficient.

Assessment and Optimization

The journey begins with a needs assessment and operational analysis to understand your specific production conditions. Then, our experts calculate the optimal pump and motor matching while providing advice on hydraulic circuit adjustments. These steps ensure the system is perfectly tailored to your needs.

Integration and Verification

We also fine-tune the servo system parameters to ensure perfect integration with your machines. Finally, we provide performance reports and follow-up monitoring to verify energy savings and ensure the maximum return on your investment.

Your professional partner for upgrading injection molding hydraulic systems.

CML leverages extensive experience in injection molding hydraulics and advanced German technology. We are committed to providing customers with optimized solutions for hydraulic energy saving and stability upgrades.

Tailored Solutions and Professional Support

Our professional team works to deeply understand your machine characteristics and production needs. We tailor the most suitable internal gear pump and servo system configurations for your specific setup. By implementing our standardized service processes, we help you achieve clear upgrades in energy consumption, precision, and overall efficiency.

Get Started with CML

Contact us today for the best advice and solutions from the CML professional team. We look forward to helping you enhance your equipment performance and market competitiveness.

- Related Products

ESG Injection Molding Machine Energy-saving Solution | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate