Vane Pump Guide: How It Works & how to choose?

Vane pumps(VP pump) are common type of hydraulic pump that uses vanes mounted on a rotor and an eccentrically placed pump chamber to repeatedly extend and retract, forming sealed chambers that draw in and discharge fluid. Compared to gear pumps, vane pumps have a somewhat more complex structure but offer a smoother output flow and lower noise. As a result, they are widely used in machine tools, plastic injection molding machines, hydraulic chuck and various automation production lines.

What’s Happening Inside a Vane Pump

The core components of a vane pump include:

- Rotor - Mounted on the pump shaft and placed eccentrically within the pump chamber.

- Vanes - Evenly inserted into the rotor slots, these slide outward under centrifugal force, hydraulic pressure, or spring force.

- Pump Chamber - The eccentric space between rotor and chamber separates the suction zone from the pressure zone.

During operation, the rotor drives the vanes to spin, and the chamber’s volume changes accordingly:

- In the suction zone, the vanes extend outward and the chamber volume expands, creating negative pressure to draw in fluid.

- 在 In the pressure zone, the vanes retract and the chamber volume decreases, forcing fluid out of the outlet. This cycle continues, enabling continuous and stable fluid delivery.

This cycle continues, enabling continuous and stable fluid delivery.

Key Features

- Stable flow output:

Ideal for hydraulic systems that require consistent pressure and precision control. - Low noise operation:

Structural design reduces hydraulic pulsation and mechanical vibration. - High efficiency:

Performs well in medium to low pressure ranges, suitable for long-term operation. - Easy maintenance:

Simple structure, convenient parts replacement, and relatively low cost of upkeep.

Common Classifications (Based on Flow Regulation)

- Fixed Displacement Vane Pumps:

Flow remains constant; suitable for applications with stable operating conditions. - Variable Displacement Vane Pumps:

Flow can be adjusted by altering the eccentricity or through control mechanisms to accommodate system pressure variations.

Typical Applications

- Machine Tool Hydraulic Systems:

Provides stable pressure to ensure machining precision. - Injection Molding Machines:

Control clamping, mold opening/closing, and injection operations. - Hydraulic Chucks and Industrial Automation:

Drive clamping, material handling, and other operations requiring low noise and stable flow.

CML – Professional Manufacturer of Vane Pumps

As a professional hydraulic product manufacturer, we deliver vane pumps with the following strengths:

- A variety of pressure and flow options.

- Various combinations of vane pumps and gear pumps.

- Rich experience in industrial applications.

- Support custom-built services.

- Hydraulic circuit design service.

- Related Products

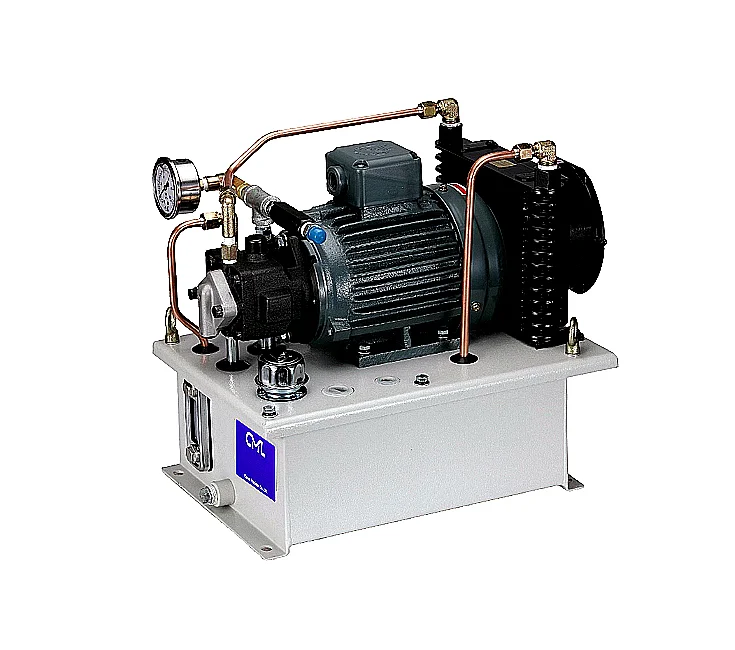

Variable Vane Pump with Cooling Circulation Pump VCM + CG

VCM-SF+CG, VCM-SM+CG, VCM-DF+CG

Variable Displacement Vane Pump with Cooling circulation pump is CML Unique and patented design. First, improve machining accuracy. By sucks in heated oil from the tank and delivers it to the radiator....

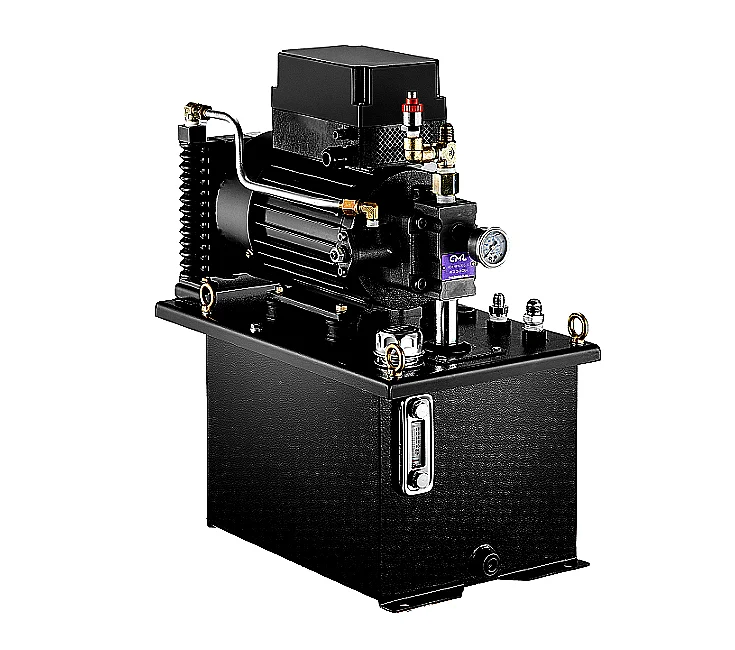

DetailsVariable Vane Pump with Built-in Check Valve SFC

VCM-SFC-24C-10, VCM-SFC-30C-10, VCM-SFC-40C-10

Variable Displacement Vane Pump with Built-in Check Valve is easy to be equipped with manifold block. The manifold block can be directly installed at the oil pump outlet, and one to multiple circuit valve...

DetailsVariable Vane Pump with Splined Shaft 7T, 9T VCM+A, VCM+B

VCM-SF-12D-30-B (9T)

Variable Displacement Vane Pump With Splined Shaft 7T, 9T makes the connection between the motor and the pump more concentricity correction function, reducing shaft wear and increasing service life. It is suitable...

Details- Files Download

Vane Pump Guide: How It Works & how to choose? | CML: ISO 9001 & CE Certified Hydraulic Pump Manufacturer – Award-Winning Quality

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate