Gear Pump Guide: How It Works & how to choose?

Gear pumps are one of the most common and reliable power sources in hydraulic systems. Whether used in machine tools, injection molding machines, or industrial equipment, gear pumps play a crucial role in converting mechanical energy into hydraulic energy. For the manufacturing industry, gear pumps offer high cost-performance value, suitability for medium- to high-pressure environments, the ability to handle highly viscous fluids, high volumetric efficiency, and stable high-flow delivery. External gear pumps are known for their compact structure and high pressure resistance, while internal gear pumps are widely used for their smooth flow and low noise characteristics. Because of these advantages, gear pumps have become indispensable core components in hydraulic systems.

What’s Happening Inside a Gear Pump?

A gear pump is a common type of positive-displacement hydraulic pump. It uses two meshing gears to draw fluid from the inlet and deliver it to the outlet. When the gears separate, fluid is drawn in; when the gears mesh, the fluid is squeezed out. This creates a series of continuously changing sealed chambers that carry the fluid forward.

- Suction Phase:When the gears disengage, a low-pressure area forms in the pump chamber, allowing external fluid to be drawn in.

- Transport Phase:Fluid is trapped between the gear teeth and the pump housing, and as the gears rotate, it is carried along the outer circumference toward the outlet.

- Discharge Phase:When the gears re-mesh, the trapped fluid is pushed out, creating a stable flow. The flow rate changes according to gear rotation speed.

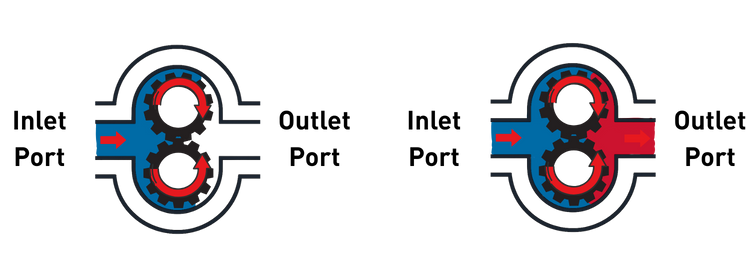

External Gear Pump Operation Diagram

When the external gear pump starts running, fluid gets pulled in from the inlet on the left side (the blue area in the diagram). As the two gears rotate, the space where their teeth separate gets larger, creating a low-pressure area that “pulls” the fluid inside. Once the fluid enters the gaps between the gear teeth and the pump housing, it gets carried around the outside of the gears. The fluid keeps moving along this outer path until it reaches the spot where the gears mesh again (the blue-to-red transition in the diagram). There, the space gets smaller, which “squeezes” the fluid and forces it out through the outlet on the right side (the red area). This whole cycle—pulling fluid in, carrying it around, and pushing it out—keeps happening as long as the gears continue turning.

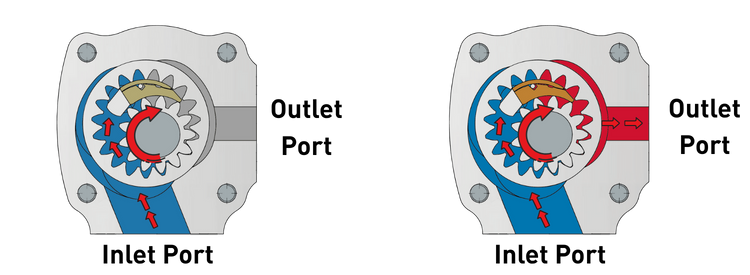

Internal Gear Pump Operation Diagram

When the internal gear pump begins to operate, fluid enters from the inlet on the left side (shown in blue). The main shaft turns the small inner gear (the rotor), which in turn drives the larger outer gear. As the teeth of the two gears move apart, the space between them increases, creating a low-pressure area that pulls fluid into the chamber formed between the gears and the pump housing.

The fluid then travels around the outside of the gears, following the curved flow path. The divider, placed between the inner and outer gears, separates the inlet side from the outlet side to prevent the fluid from short-circuiting back to the suction area.

As the fluid continues to move with the gears and reaches the point where the gear teeth mesh again, the available volume decreases. This compression forces the fluid out through the outlet on the right side (the red area). This continuous cycle of drawing in, carrying around, and pushing out fluid creates a smooth and steady flow.

Which one is better Internal vs. External?

Although the operation of gear pumps use the same basic principle, they can be classified into external gear pumps and internal gear pumps based on different gear arrangement. Each type has unique structural features and advantages, making them suitable for different industries and applications.

Advantages of External Gear Pumps:

- Pressure & Flow: Commonly used in medium-pressure systems (approx. 100–200 bar) and suitable for high-flow applications.

- Efficiency: Volumetric efficiency generally exceeds 90%.

- Fluid Compatibility: Capable of handling highly viscous fluids.

- Cost & Maintenance: Easy to maintain and highly cost-effective.

Points to Note:

- Noise: Larger flow pulsation results in higher noise levels; long-term operation may require noise-control considerations.

- Service Life: Prolonged high-speed or high-temperature operation increases wear and reduces lifespan.

Typical Applications

Widely used in agricultural machinery, industrial equipment, mobile machinery (such as forklifts and excavators), and lubrication systems.

Advantages of Internal Gear Pumps:

- Pressure & Flow: Suitable for medium-high to high-pressure systems (200 bar or above) and high-flow requirements.

- Efficiency:: Volumetric efficiency can reach above 93%. Equipped with radial and axial pressure compensation, slowing efficiency degradation over long-term operation.

- Noise: Low flow pulsation (especially at high speeds), smooth output, and low noise—ideal for precision-control or noise-sensitive environments.

- Durability: Radial and axial pressure compensation enhances adaptability to high pressure and high temperature, offering longer service life.

- Multiple pumps can be assembled in series to meet flow rate requirements.

Points to Note

- Cost & Maintenance:More complex structure requiring high-precision machining and assembly; therefore, cost is higher.

- Oil Cleanliness Requirements:There are higher requirements for oil cleanliness, and a filter screen with higher filtration precision should be selected according to the conditions.

Typical Applications

Commonly used in manufacturing machinery, metal processing equipment, mobile machinery, hydraulic systems, servo systems, and electro-hydraulic integrated solutions. These applications usually require strict oil temperature control, high efficiency, and high precision—areas where internal gear pumps perform exceptionally well with their low noise and stable output.

| Feature | External Gear Pump | Internal Gear Pump |

|---|---|---|

| Structural Design | Simple structure, easy maintenance | More complex, requires high-precision machining |

| Pressure & Flow | Medium pressure (100–200 bar), suitable for high flow | Medium-high to high pressure (200+ bar), suitable for high flow |

| Efficiency | Good | Excellent, with radial & axial pressure compensation |

| Noise | Very quiet | |

| Service Life | Excellent | |

| Viscosity Compatibility | Wide | Wider |

| Cost & Maintenance | Cost-effective |

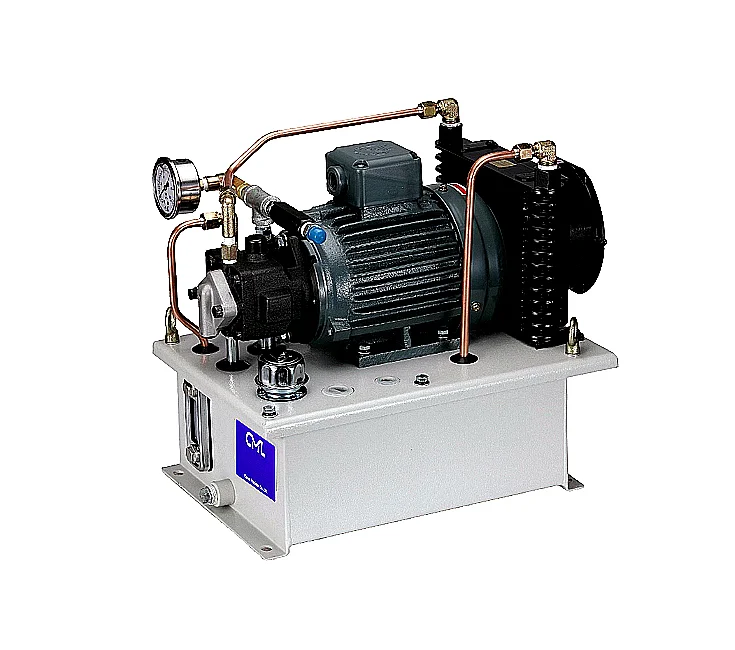

CML – Professional Manufacturer of Internal & External Gear Pumps

CML has nearly 45 years of industry experience and a proven track record in developing and integrating both internal and external gear pump solutions. We are also the first manufacturer of internal gear pumps in Taiwan.

Since 2001, CML has been the exclusive distributor for Eckerle in Asia, forming a long-term partnership that has strengthened our manufacturing capabilities and expanded our product portfolio.

For multi-stage pump configurations, CML professional team is authorized in assembly technology, enabling flexible combinations of imported Eckerle pumps and Taiwan-made pumps—balancing high efficiency, low noise, and cost-effectiveness.

CML offers a wide range of pressure and flow specifications, optimized based on different industries and equipment characteristics, supporting applications from high-pressure stable output to energy-efficient systems.

- Related Products

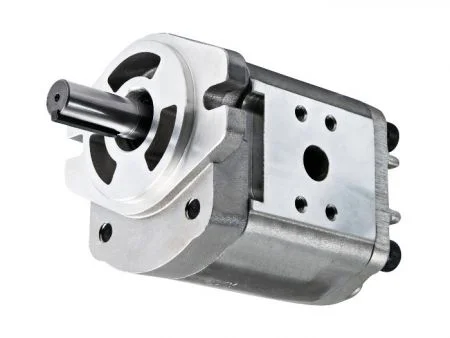

A Series Compact Low noise External Gear Pump EGA

EGA-1.2-R, EGA-6.2-R, [Previous model EG4-10]

A Series, the compact low-noise external gear pump, EGA is right for the working conditions that need small flow and medium-high pressure. With aluminum extrusion body and special steel gears, plus the fine...

DetailsC Series Low Pulsation External Gear Pump EGC

EGC-19-R, EGC-26-R, [Previous model EG4-36]

C series low-pulse external gear pump, EGC is mostly used in shoemaking machine and machines for special application. It has the characteristics of high-pressure and high-efficiency, as well as a small...

DetailsVariable Vane Pump with External Gear Pump Series VCM + EGA

VCM-SF-30C-20 / EGA-6.2-R

The combined application of variable vane pump and external gear pump series share a single motor. It not only saves cost and installation space, but also combines the low noise of the vane pump and the high-pressure...

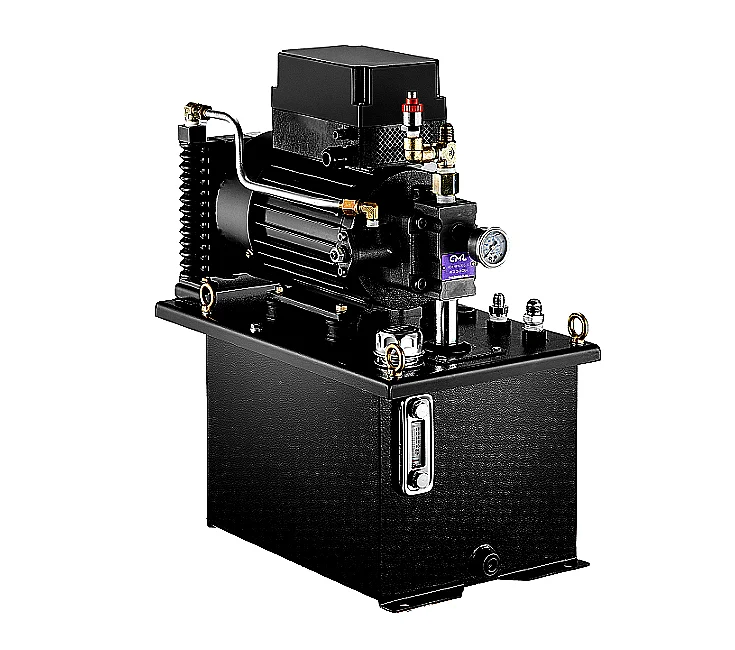

DetailsCML Combine Eckerle Multiple Gear Pump CML + ECKERLE

CML+ECKERLE, IGP+EIPC, IGP+EIPS, EIPH+IGP

The multiple pumps with Eckerle and CML internal gear pumps integrated can comprise various pump sizes with different pressure output, supporting users with miscellaneous options for their applications....

Details

Gear Pump Guide: How It Works & how to choose? | CML: ISO 9001 & CE Certified Hydraulic Pump Manufacturer – Award-Winning Quality

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate