Machine Tool Energy-Saving Solutions

CML has nearly 45 years of hydraulic expertise, supported by a professional team covering product design, manufacturing, and customer service.

Have you ever struggled with accuracy drift caused by rising oil temp.?Your electricity bills, hydraulic oil consumption, and maintenance costs can actually be lower!

In today’s machine tool industry, rising energy prices and strict carbon-emission regulations have become major pressures. Performance alone is no longer enough. Energy efficiency, stability, and sustainability now define true competitiveness. This is where CML creates value. With decades of engineering experience, delivering high-efficiency pumps, customized hydraulic systems, hybrid energy-saving solutions, and precise oil-temperature control for machine tools.

CML is more than a hydraulic supplier. We drive industry progress.To support customers worldwide, CML ensures fast global response through efficient air and sea freight logistics. Many of our long-term partners, after gaining deep familiarity with CML products and local market needs, have become regional distributors—creating strong, mutually beneficial collaborations.

The best solutions come from real collaboration. CML works closely with customers to understand their needs and develop hydraulic systems that match their machines. We also coordinate with related suppliers to ensure full compatibility across all components.Each project begins with a clear understanding of the customer’s process and challenges. This allows our team to create solutions that are both practical and accurate.

Using professional instruments such as HIOKI power analyzers, CML starts each project with precise on-site measurements. After presenting an initial concept, we review specifications and cost together with the customer and begin drafting the system design until the final solution is confirmed.

Once the product is completed and installed, CML provides optimized setup recommendations and verifies operating conditions on site to ensure system stability.

After installation, we continue to follow up and collect feedback to further refine our service. Through this complete workflow, CML becomes not only a supplier, but a long-term partner that grows together with our customers.

High-Efficiency Solutions For Machine Tool Challenges

Ready to cut your energy costs? / Need reliable oil-temperature control?

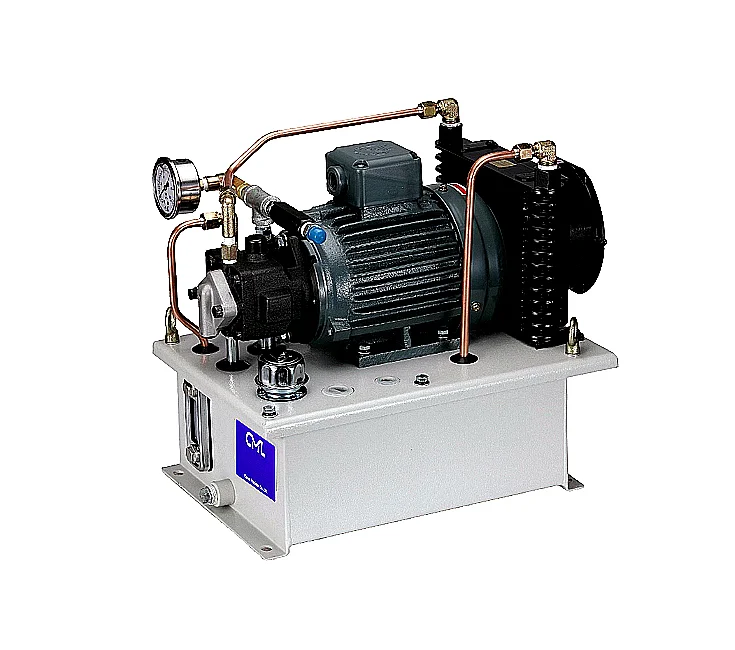

HPU Series Energy-saving Hybrid Power Unit | 40% - 60% Energy-saving

Long pressure-holding times and older machines often cause problems like rising oil temperature, loud noise, and high energy use. CML provides a professional solution with the HPU Series Energy-saving Hybrid Power Unit. These systems stabilize oil temperature, reduce noise, cut energy and hydraulic-oil consumption, extend machine lifespan, and help maintain consistent machining accuracy and productivity.

By combining an inverter drive with a high-efficiency IE3 motor, the system lowers motor speed during pressure-holding, achieving 40–60% energy savings and reducing noise by 6 dB. It also keeps oil temperature within a 2.5°C rise above room temperature, ensuring machining accuracy and extending component life.

In addition, maintaining stable oil temperature allows the oil tank size to be reduced by 40–60%, optimizing machine layout and lowering hydraulic oil consumption. Because the inverter and hydraulic system are integrated into a single unit, installation is quick and straightforward—simply connect the motor power cable with no extra wiring or external control cabinet required. This further reduces material and cooler costs while supporting energy efficiency and sustainability.

In a successful case with Processing Machine, CML upgraded the customer’s original 2 HP/4P - 220V motor to a high-efficiency IE3 2 HP - 220V motor, paired with the optimized CML variable displacement pump VCM-SFN-20C.

In a successful case with CNC Lathe, CML team evaluated the customer’s requirements and confirmed that a 2 HP motor was sufficient for the operating conditions. The customer’s original 3HP/4P - 220V motor was upgraded to a high-efficiency IE3 2 HP - 220V motor, paired with the optimized CML variable displacement pump VCM-SF-30C-20.

A 24-hour energy test showed a significant reduction in power consumption, dropping from 17.82 kWh to 9.83 kWh, which is a 55% energy saving. This reduces operating costs and also prevents unnecessary energy waste and high oil temperature.

After evaluation by the CML team, traditional hydraulic systems can be upgraded by an inverter drive, replacing the motor with a high-efficiency IE3 model, and selecting a suitable pump. With these improvements, a Processing Machine can achieve approximately 53% energy savings, while a CNC Lathe can reach about 55%. The older the machine, the greater the improvement after the upgrade.

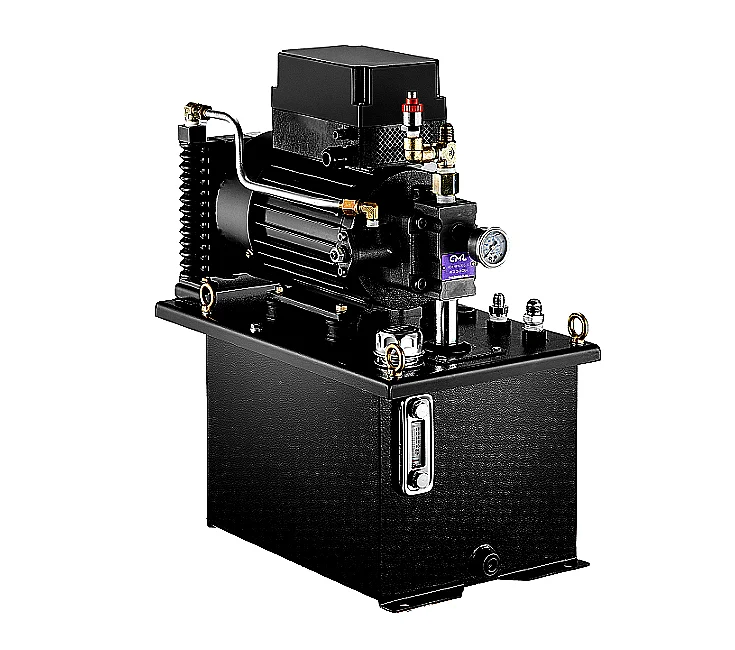

SPU Series Cooling Circulation Power Unit | Reduce Oil Temperature by 20%

CML offers a professional cooling solution with SPU Series Cooling Circulation Power Unit. The SPU Series delivers more than three times the cooling performance of traditional systems, effectively addressing issues such as hydraulic overheating, limited machine space, and unstable machining accuracy.

By solving these problems at the source, the SPU Series helps manufacturers achieve higher efficiency, improved energy savings, and long-term sustainability.

The design combines a patented variable vane pump with a cooling circulation pump, delivering 4 to 6 liters of hot oil per minute to the cooler. This high-flow circulation allows the system to reduce oil temperature by 20%, making the solution especially suitable for machine tools with frequent machining movements. The enhanced cooling performance helps stabilize machining accuracy, reduce oil tank size, lower material and hydraulic oil usage, and extend component life, ultimately reducing overall operating costs.

During operation, continuous flow from the circulation pump is matched with the cooler’s heat-dissipation capacity through thermal calculations. Heat generated from internal leakage and machine operation is directed to the hot-oil zone of the tank and then routed into the cooler for stable and efficient cooling. This process keeps the oil temperature consistently lower throughout long operating periods.

Performance comparisons show that the variable vane pump with cooling circulation (VCM + CG) reaches temperature stability within 1 to 2 hours after startup. After 7 hours of continuous operation, the oil temperature in the tank remains nearly 20% lower than systems equipped with standard pumps.

CML delivers professional hydraulic solutions that enhance precision, efficiency, and sustainability for machine tool manufacturers.

The company is more than a supplier of hydraulic components. CML provides complete hydraulic system solutions that help the industry achieve higher accuracy, higher efficiency, and more stable production. This system-level approach allows customers to achieve reliable performance across the entire machine instead of focusing only on individual parts.

With more than 40 years of hydraulic expertise and industry experience, CML supports a wide range of equipment—including lathes, machining centers, grinders, and saw machines—through solutions that lower oil temperature, reduce energy consumption, and minimize system footprint. These improvements strengthen machining stability and consistency, allowing customers to operate more efficiently and with greater confidence.

CML remains committed to helping manufacturers build machine tools that are not only energy-efficient and environmentally responsible but also highly competitive in today’s global market.

Machine Tool Energy-Saving Solutions | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate