.png?v=dc917116)

2024 IMTS Exhibition

Camel Precision Co., Ltd (CML) will attend the 2024 IMTS, North America's premier machinery manufacturing exhibition, in September 2024. CML is committed to product development and design in the spirit of "Sustainable Environmental Protection". At IMTS 2024, CML will show you cost-effective "Energy-Saving" and "Cooling-Solution" related products with over 40 years of experience in the hydraulics field.

Welcome to explore this platform that allows the manufacturing technology community to learn about the personalities that drive the industry, gain insights on new technology, and make connections with us!

Since 1981, CML has been committed to the production of hydraulic products and assisted customers in creating customized hydraulic stations and hydraulic systems. By offering services for more than 3,000 companies and expanding the market to five continents, CML also has sold Eckerle internal gear pumps to Asia for nearly 20 years.

Exhibtion Information

- Exhibition period: Sep. 9 to 14, 2024, 6 days in total.

- Booth name: Camel Precision Co,. Ltd.

- Exhibition location: McCormick Place in Chicago

- Booth location: North Building, Level 3

- Booth number: 236053 - Automation

Exhibits

Customized High Pressure Coolant Through Spindle (CTS) application

Coolant Through Spindle also known as Through-Spindle Coolant (TSC), is a critical technology for modern drilling machines, especially for High speed industrial drill. High Pressure Machine Tool Coolant Delivery allows for heavier cuts, higher feed rates, deep-hole drilling, and better surface finishes. Coolant Through Spindle has the advantage of quickly removing chips for better surface finishes, reducing cycle time, using less materials, and extending tool life, etc.Combined with a high pressure pump, is the main key to affect the performance and determines the machine life. CML provides CTS matching with pump service, which is the right choice for you in Central Coolant System.

High-Pressure Diaphragm Pump- MPD

CML High-Pressure Diaphragm Pump- MPD is a new product that offers "High-Pressure Coolant Solution" and "Energy Saving ", and it can meet the requirements of high-pressure coolant through spindle. MPD High-Pressure Diaphragm Pump has been upgraded from single to multiple diaphragms, which successfully reduce problems such as temperature rise, noise, and pulsation. The structure design combines plunger, gerotor, and diaphragm for better performance in central coolant systems. MPD High-Pressure Diaphragm Pump has five major benefits: noise reduction, high efficiency, energy saving, durability, strength, and stable temperature control. CML has the upper hand in the market with our structural advantages, wide range of applications, and standardized design.

- A new product for high pressure coolant through spindle (CTS) solution.

- Max. Pressure: 100 bar+ (1400+psi)

- Energy Saving

SFC Uni Pump

CML SFC Uni Pump has a motor that is more efficient than IE3, and it allows direct installation of manifold block and pressure gauge to save space, which is an indispensable advantage in the design of recent mechanical structures. Variable Displacement Vane Pump with Built-in Check Valve can be easily equipped with manifold block. The manifold block can be installed directly at the oil pump outlet, and one to multiple circuit valve groups can be added to achieve integrated functions and save space and piping length. There is also a pressure gauge hole on the back of the oil pump, which can be directly attached to the pressure gauge. By reducing the amount of external oil leakage, the heating of the fuel tank is reduced, and the operation is stable, wear-resistant, energy-saving, low-noise and long-lasting.

- IE3 Electric motor with UL certificate.

- Compact: Direct installation of manifold block and pressure gauge to save space.

- More economical and affordable compared with other brands.

- CML will present different Cartridge Valves which are compatible for RAH, RDH, FV, DSL, PRH, CVH, CBCA, RVCA, SP, PV, TS and more product series.

- Various function: Relief, Reducing, Solenoid, Check, Counterbalance, Proportional, etc.

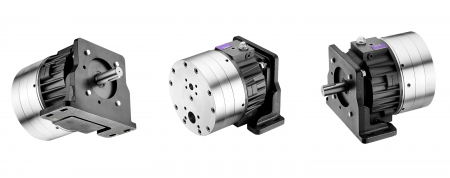

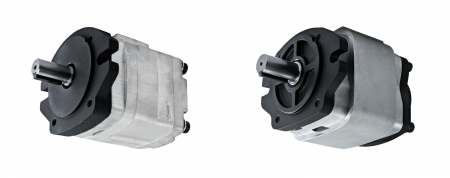

Internal Gear Pump Series

CML Internal Gear Pump Series are widely used in all kinds of manufacturing machinery, metal processing machinery, mobile machinery, hydraulic systems, servo systems, and integrated hydraulic oil and electricity application.Combining the characteristics of different Hydraulic pumps to achieve low noise creates a friendly working environment, low energy consumption joins environmental protection. Low consumption for cost-saving, etc., Most importantly, it can greatly improve the accuracy and stability of mechanical operation and maximize customer benefits.

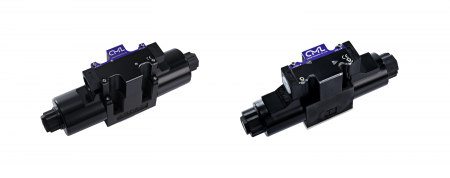

High Flow Type Solenoid Valve - WH

CML solenoid valves are used in the direction switching operation of machine tools, metal processing machinery, and various hydraulic systems. Small size, sensitive switch action, fast switching, and high efficiency. Applicable to international standards such as ISO, CETOP, NFPA, and DIN. The WH series has two sizes, 6-diameter, and 10-diameter, with a maximum operating pressure of 210 bar, a maximum allowable back pressure of 100 bar, and a flow range of 63 ~ 120 (LPM). There is a complete range of products, and spool type can be selected according to the needs of the circuit, and products with reverse assembly can be supplied.

Compact Adjustable Hydraulic Pressure Switch-CPS14

CML Compact Adjustable Hydraulic Pressure Switch widely used in hydraulic systems. CPS14 is designed for space-saving requirements. Compared with CPS01, which is about 85.5mm in height and 47.5mm in width, CPS14 is only 76.3mm in height and 31mm in width, so it is the best choice for your compact design. CML highly recommends installing a pressure switch in the system. This way, when the pressure deviates from the set value, it can send a signal to alert the situation and protect the system from damage.CML supplies two types of installation and adjustment, respectively. The installation can be further divided into pipe connection type and subplate connection type; the adjusting type can be further divided into Manual adjusted and Hex key adjusted, life expectancy of up to 1,000,000 times. Customers can select the most cost-effective and suitable products based on their specific requirements.

Exhibition record

CML participated in IMTS 2024 in Chicago, showcasing our latest energy-saving and cooling solutions. We were honored to join the product launch event hosted by TAITRA. The exhibition attracted over 15 visitors from various continents, providing us with opportunities to engage with industry experts and potential clients. These valuable interactions have helped us better understand market needs and shape our future strategies.

- Exhibition Highlights

- Related Products

Variable Vane Pump with Built-in Check Valve SFC

VCM-SFC-24C-10, VCM-SFC-30C-10, VCM-SFC-40C-10

Variable Displacement Vane Pump with Built-in Check Valve is easy to be equipped with manifold block. The manifold block can be directly installed at the oil pump outlet, and one to multiple circuit valve...

Details

2024 IMTS Exhibition | Globally Certified Hydraulic Valves & Pumps – CML Wins 2024 REBRAND 100® Award

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate

Trending Now

With 40+ years of experience, CML excels in cross-border and cross-industry collaborations, developing energy-efficient solutions for a sustainable.

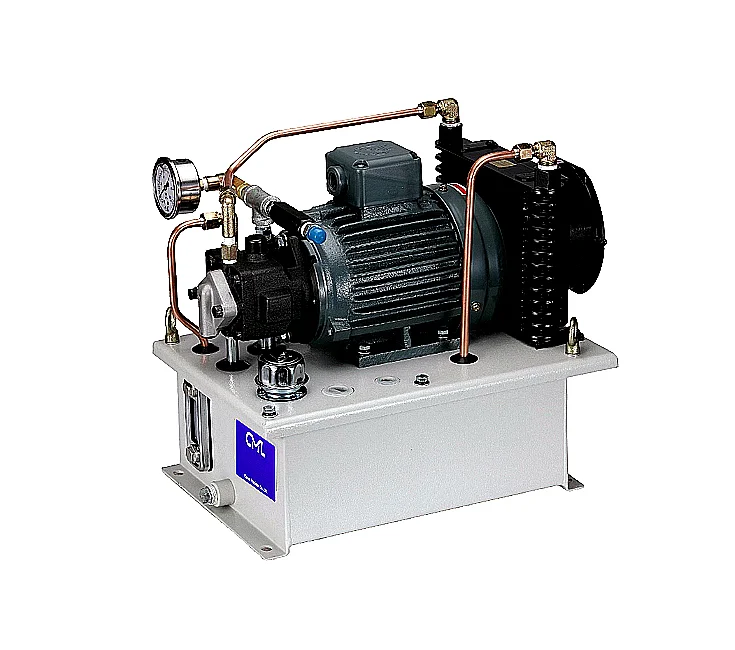

Cooling Circulation Power

Hot-Selling ProductsStabilizes oil temp. (avg. -20%) while reducing tank size, oil use, and boosting processing accuracy and stability.

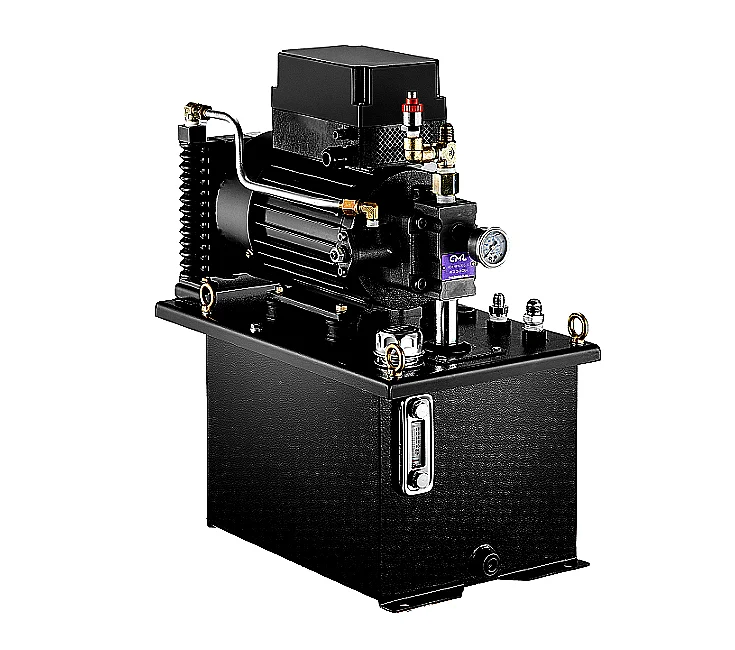

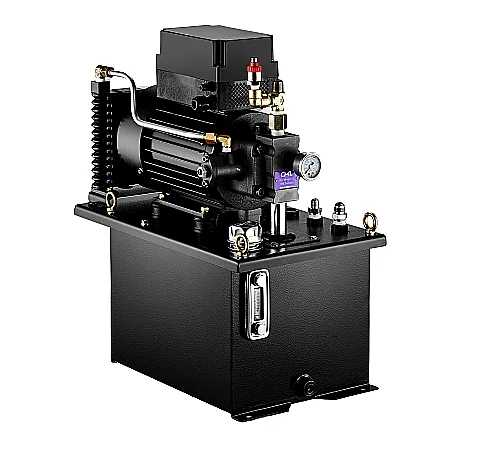

Energy-saving Hybrid Power Unit

Hot-Selling ProductsPrecise oil temp. (+/- 2.5°C of ambient) with 40-60% power & size reduction, and 6dB noise cut.

Orbital Hydraulic Motor

BMM, BMP, BMPHCompact, efficient, and powerful. Ideal for construction, injection molding, machine tools, metallurgy, and agriculture.

High-Pressure Diaphragm Pump

MPDWith up to 100 bar pressure, this pump combines piston, diaphragm & gear tech to reduce heat and extend service life.

.jpg?v=d0627105)

.jpg?v=92427aea)

.jpg?v=d187c610)

.jpg?v=60bf226b)

.jpg?v=b5fc85e9)

.jpg?v=b5335364)

.jpg?v=36a8c78d)

.jpg?v=b33dda74)

.jpg?v=dca322d2)

.JPG?v=b49d22dd)