BMM series Small Displacement Orbital Hydraulic Motor

BMM

CML BMM series small displacement orbital hydraulic motor, a compact axial-flow-distribution motor engineered for installations where space is limited. Featuring an integrated rotor and stator with a 4/5-tooth design, this motor delivers lightweight construction, high power density, and smooth, linear power output.

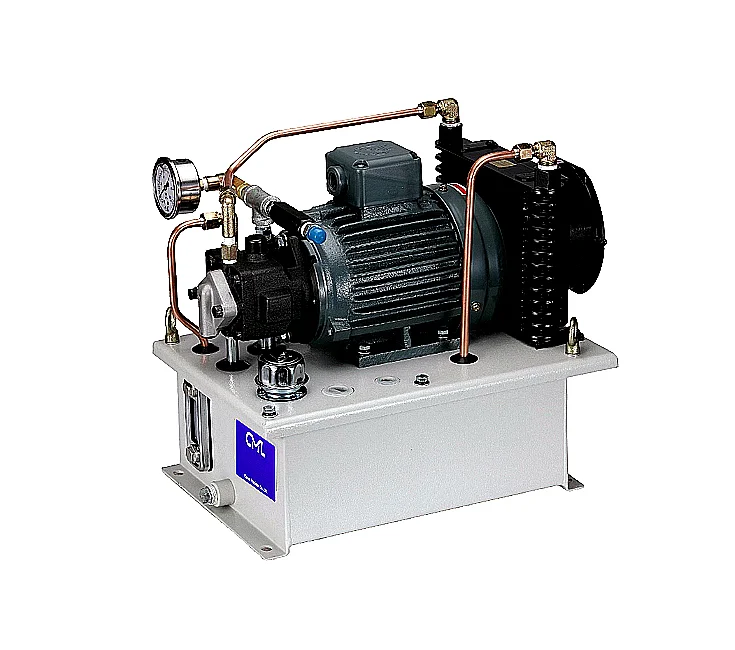

Media Gallerys

-

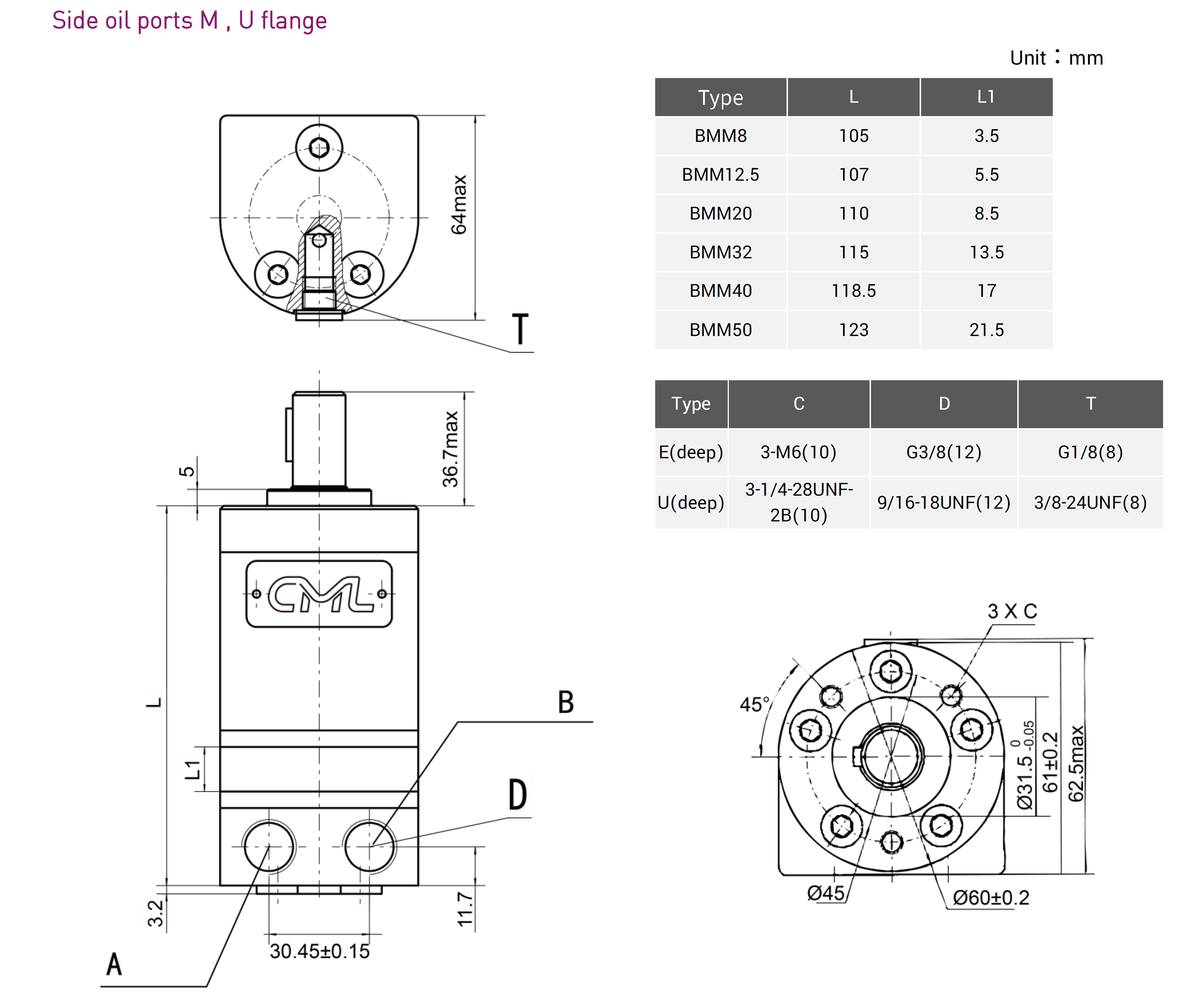

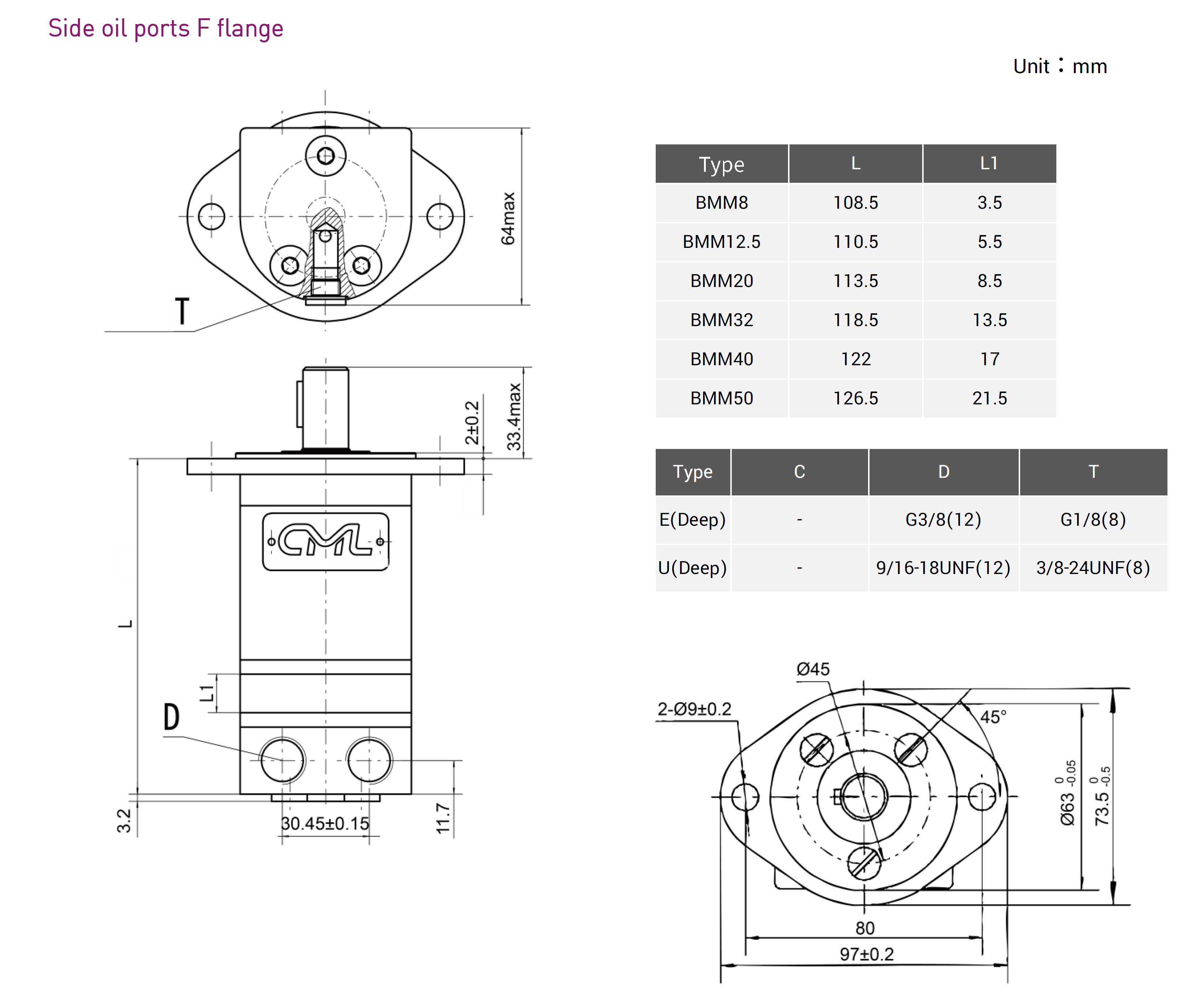

CML BMM Series Small Displacement Orbital Hydraulic Motor Side Oil Port Type.

-

CML BMM Series Small Displacement Orbital Hydraulic Motor Side Oil Port Type Buttom.

-

CML BMM Series Small Displacement Orbital Hydraulic Motor Side Oil Port Type Buttom.

-

CML BMM Series Small Displacement Orbital Hydraulic Motor Side Oil Port Type Connection Surface.

-

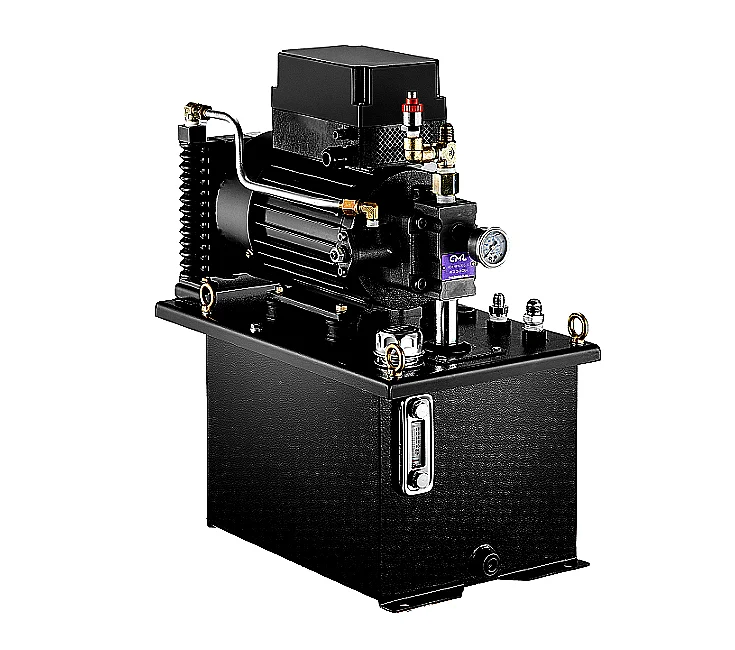

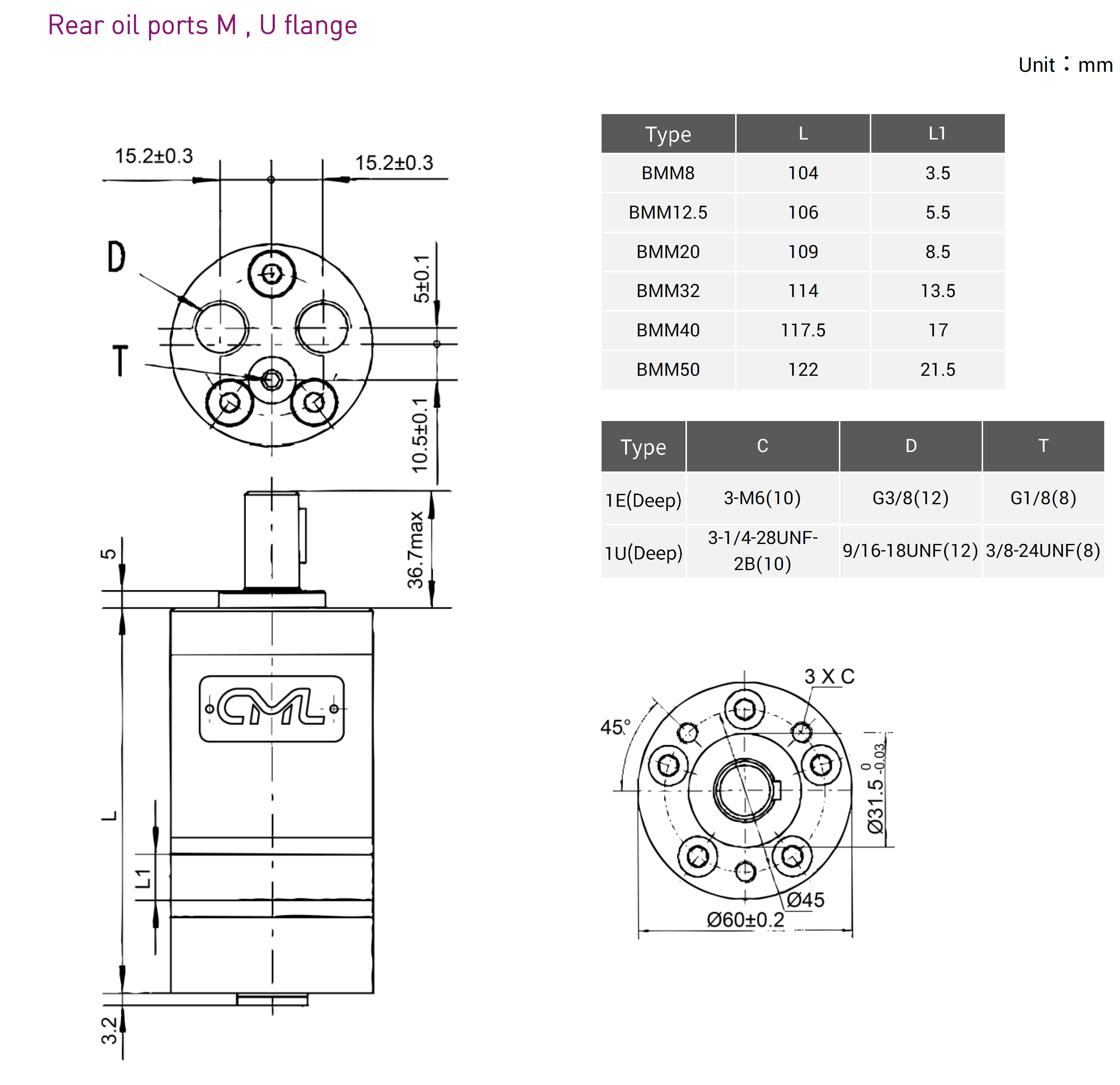

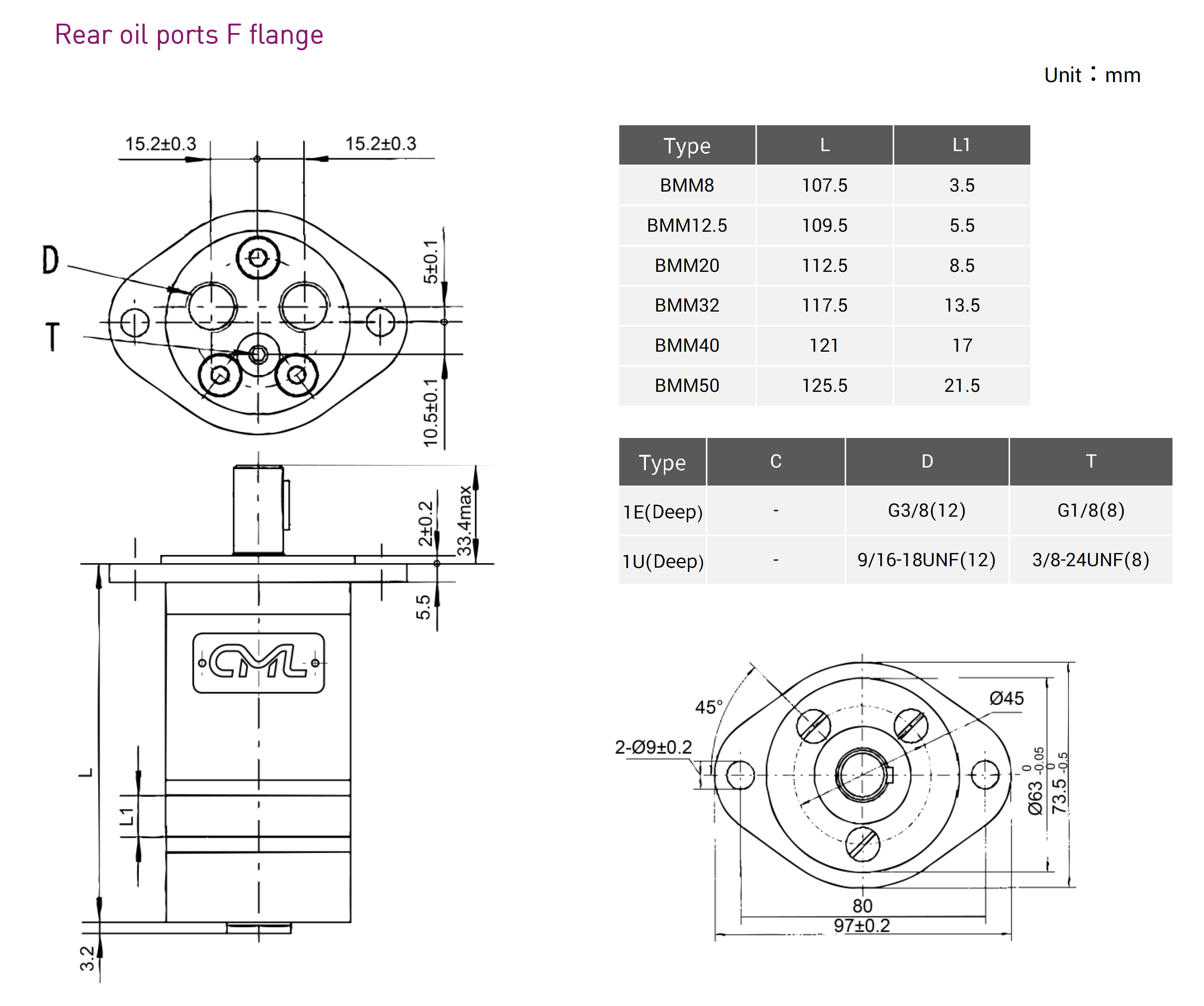

CML BMM Series Small Displacement Orbital Hydraulic Motor Rear Oil Ports Type.

-

CML BMM Series Small Displacement Orbital Hydraulic Motor Rear Oil Ports Type.

-

CML BMM Series Small Displacement Orbital Hydraulic Motor Rear Oil Ports Type Drain.

-

CML BMM Series Small Displacement Orbital Hydraulic Motor Rear Oil Ports Type Connection Surface.

Available in displacements from 8 to 50 c.c./rev., the BMM series supports multiple configurations, including round or diamond mounting flanges, keyed or splined shafts, side or rear ports, and both clockwise and counterclockwise rotation. An optional external drain port is also available, providing enhanced flexibility and reliable performance across a wide range of industrial and mobile hydraulic systems.

Feature

- The integrated stator adopts the world's advanced processing technology to ensure the whole motor is small in size, high efficiency, high speed and long life.

- The shaft seal is high-pressure-bearing and can be used in serial or parallel.

- Advanced structural design, high power and high torque.

Application

- Construction machinery : widely used in construction machinery such as excavators, cranes and loaders. It is mainly used to drive working devices, such as slewing mechanisms and walking mechanisms. Due to its high torque and high efficiency characteristics, it can effectively improve working efficiency.

- Machine tool industry : suitable for spindle drive, providing high-speed and high-precision power to meet the demand for high-speed machining.

- Saw machine industry : It can be used with wire brushes for rolling chips during processing and removing iron chips.

- Injection molding machinery : As one of the main driving elements of the injection molding machine, it converts mechanical energy into hydraulic energy, drives the opening and closing of the mold and feeds the hopper, etc.

- Metallurgical industry : plays an important role in the start, stop and control of metallurgical equipment, suitable for use in various metallurgical processing equipment

- Agricultural equipment : used in various agricultural machinery, such as tractors and harvesters.

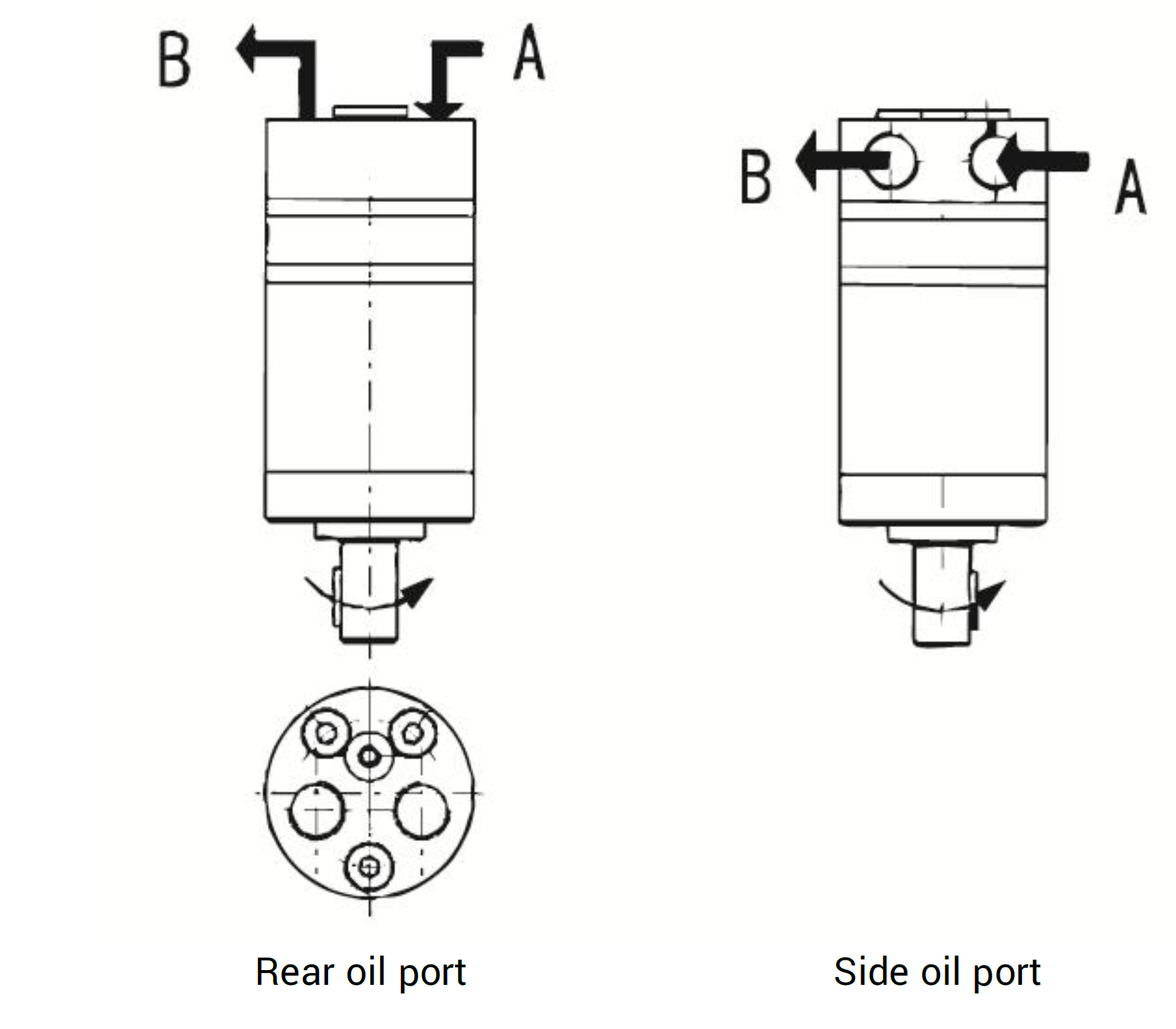

Direction of shaft rotation

Facing the shaft, if the A port is high-pressure oil, the shaft rotates clockwise; otherwise, it rotates counterclockwise.

Performance

CML provides optimal torque (N•m) data in our catalogs, corresponding to specific flow rates (RPM) and pressures.

More Information

CML provides detailed information and charts in our catalogs regarding the radial torque against the shaft and the pressure allowed for shaft sea of our hydraulic motors.

For more detailed information, please scroll down to the "Download" tab to download our catalog, or contact the CML sales team.

- Code

-

Model Code

Product Series Displacement Mounting surface type Shaft type Port specs Direction ofrotation Painting Options Special features BMM 8 M A E * 00 * Displacement:

8、12.5、20、32、40、50

Mounting surface type:

M: 3-M6 Round flange, Outlet Ø31.5×5

U: 3-1/4-28UNF Round flange, Outlet Ø31.5×5

F:2-Ø9 Rhombus flange, Outlet Ø63×2Shaft type:

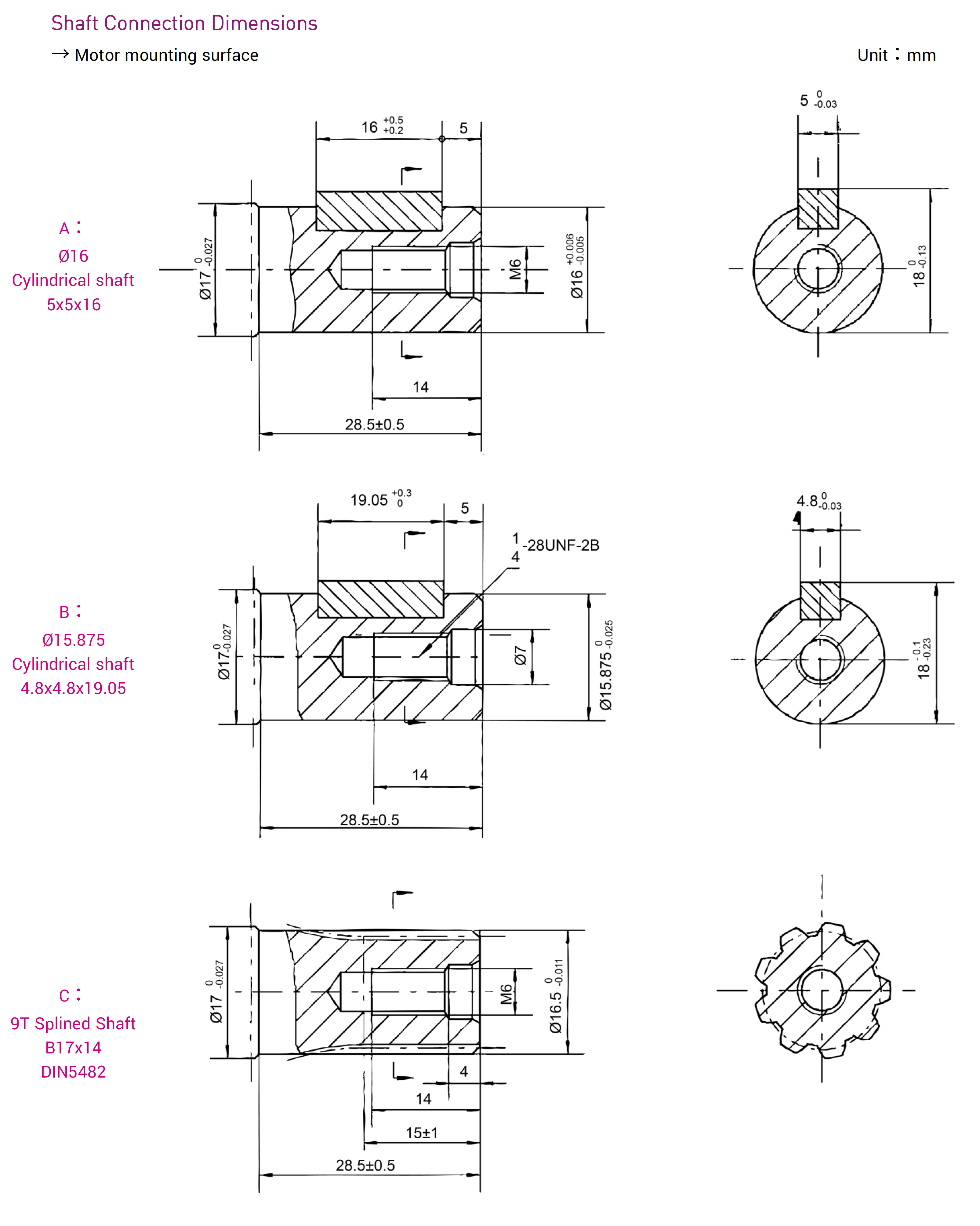

A: Ø16,Cylindrical shaft5×5×16

B: Ø15.875,Cylindrical shaft4.8×4.8×19.05

C: Ø16.5,Spline shaftB17×14,DIN5482Port specs:

E: Side G3/8DrainG1/8

U: Side9/16-18UNFDrain3/8-24UNF

1E: RearG3/8DrainG1/8

1U: Rear9/16-18UNFDrain3/8-24UNFDirection of rotation:

*None: Clockwise

R: CounterclockwisePainting Options:

B: Black

*None: Blue

00: No pain

S: Silver graySpecial features:

*None: Drain

0: No Drain - Data

-

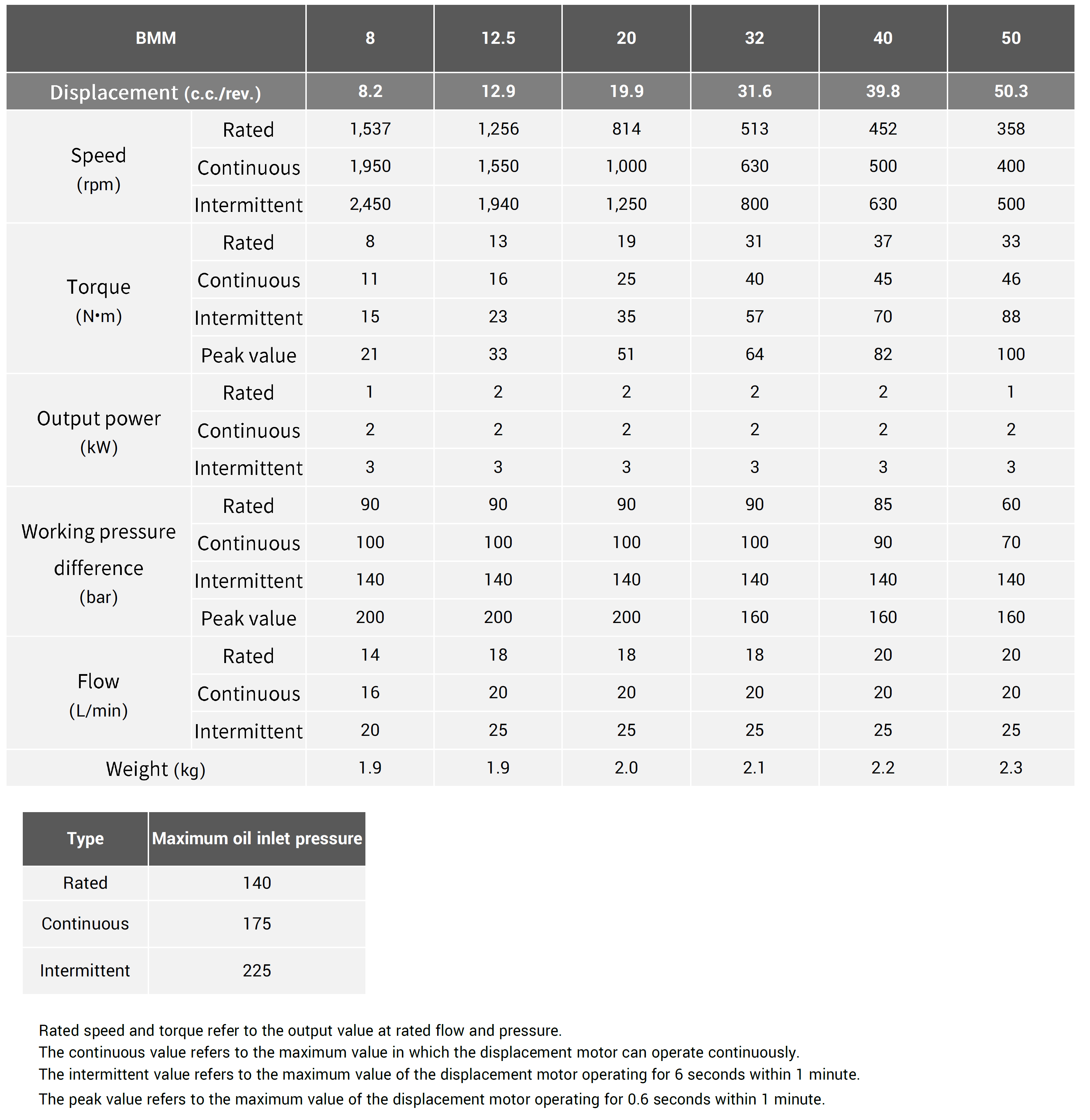

Technical Data

In different displacement scenarios, the corresponding technical data includes values for speed (rpm), torque (N•m), output power (kW), working pressure difference (bar), flow (L/min), weight (kg), and maximum inlet pressure (bar). These figures are provided for rated, continuous, intermittent, and peak operating conditions.

- Rated speed and torque refer to the output value at rated flow and pressure.

- The continuous value refers to the maximum value at which the displacement motor can operate continuously.

- The intermittent value refers to the maximum value of the displacement motor operating for 6 seconds within 1 minute.

- The peak value refers to the maximum value of the displacement motor operating for 0.6 seconds within 1 minute.

- DWG

-

Measurement

- Notice

-

Optimal Operating Conditions

- Oil Temperature: Normal working range 20℃-60℃, maximum system temperature 90℃ (not exceeding 1 hour).

- Oil Filtration & Cleanliness: Oil filter precision 80-100 microns (150-180 mesh). Magnetic blocks recommended at the bottom of the tank to prevent metal debris from entering the system. Hydraulic oil contamination level should not exceed ISO 19/16 (NAS-10 level).

- Oil Viscosity: Kinematic viscosity at 40℃ should be 42-74 cSt, depending on operational and environmental conditions.

- Motor Connection: Can be used in series or parallel. If back pressure exceeds 100 bar (speed below 200 rpm), an external drain port must be used, preferably connecting it directly to the oil tank.

- Best Operating Range: Select operation within continuous maximum limits.

- Extended Motor Life: Before applying full load, operate at 30% of rated pressure for approximately 1 hour. Always ensure the motor is fully filled with hydraulic oil before applying load.

For special requirements, please contact us.

Series Data List

Model Displacement

(c.c./rev.)Max. pressure

(bar)Speed

(rpm)Output power

(kW)BMM 8~50 140 40-1950 3.2 - Download

BMM series Small Displacement Orbital Hydraulic Motor | EMC, ISO 9001, and CE Certified Hydraulic Valves – CML’s Global Recognition

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a BMM series Small Displacement Orbital Hydraulic Motor (model: BMM ) manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate