Eckerle Internal Gear Pump EIPC - High-quality Eckerle Internal Gear Pump EIPC manufacturer from Taiwan | Camel Precision Co., Ltd.

CML, Camel Hydraulic, Camel Precision is a Taiwan based high-quality Eckerle Internal Gear Pump EIPC manufacturer and Eckerle Internal Gear Pump EIPC supplier With more than 40 years experience, CML is specialized in Vane Pump, internal gear pump, external gear pump, solenoid valve, modular valve, flow control valve, pressure control valve, check valve, servo system, power unit, hydraulic pump, hydraulic valve, hydraulic accessory manufacture. since 1981.

Eckerle Internal Gear Pump EIPC

EIPC3,EIPC5,EIPC6

Eckerle Internal Gear Pump

The multiple pumps with Eckerle and CML internal gear pumps integrated can comprise various pump sizes with different pressure output, supporting users with miscellaneous options for their applications. It is made for fixed RPM or servo systems for different working situations, like continuous stable pressure holding and/or hydraulic mechanical applications that require different pressure outputs, to satisfy both quick operating speed and high-pressure requirements.

Application examples: pipe crimping machine (pipe connector clamping), cutting machine, material compactor, etc. Custom specs are available; please contact us for more details.

CML's products are widely used in all kinds of manufacturing machinery, metal processing machinery, mobile machinery, hydraulic systems, servo systems, and integrated hydraulic oil and electricity application.

Combining the characteristics of different Hydraulic pumps to achieve low noise creates a friendly working environment; low energy consumption joins environmental protection. Low consumption for cost-saving, etc., Most importantly, it can greatly improve the accuracy and stability of mechanical operation and maximize customer benefits.

Feature

- Internal gear pump with axial and radial gap compensation

- Radial compensation with segments

- Suction and pressure port radial

- Field of application: Industrial hydraulic

- Low noise

- Long time life

- Low pulsation (pressure pulsation ~2 %)

- Multi flow combinations

Application

- Suitable for injection molding machines, molding machines, servo-hydraulic energy saving systems and other high pressure hydraulic machines.

Specification

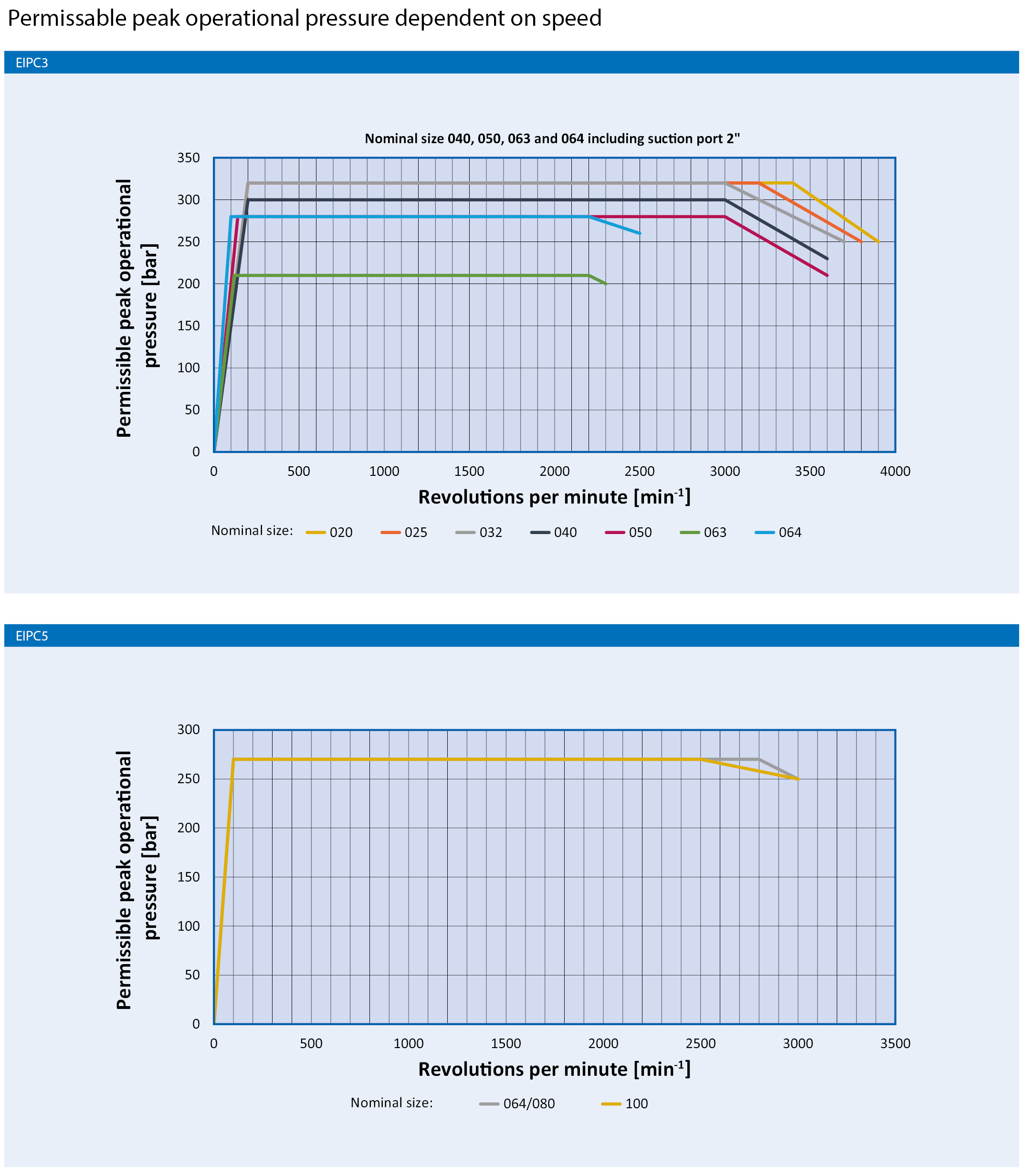

EIPC3 Series

Testing condition:n = 1.450 min-1,Δ p = 250 bar,T = 50 °C,Medium: HLP 46

| Rated Size | 020 | 025 | 032 | 040 | 050 | 063 | 064 |

|---|---|---|---|---|---|---|---|

| Spec. volume Vth [cm3/rev]*** | 20.0 | 24.8 | 32.1 | 40.1 | 50.3 | 63.1 | 64.4 |

| Continuous operating pressure [bar]** | 250 | 180 | 250 | ||||

| Peak operating pressure [bar] max. 10 sec 15 % duty cycle** |

320 | 300 | 280 | 210 | 280 | ||

| Cut-in pressure peak [bar]** | 350 | 325 | 300 | 210 | 300 | ||

| Nominal speed [min-1] | 200 - 3.400 | 200 - 3.200 | 200 - 3.000 | 100 - 2.500 | 100 - 1.800 | 100-1.800 | |

| Max. speed [min-1] | 3.900 | 3.800 | 3.700 | 2.500 | 1.800 | 1.800 | |

| Nominal speed [min-1]**** | 100 - 3.200 | 100 - 3.000 | 200 - 2.200 | 100-2.200 | |||

| Max. speed [min-1]**** | 3.600 | 3.600 | 2.400 | 2.400 | |||

| Operating viscosity [mm2/s] | 10 - 300 | ||||||

| Starting viscosity [mm2/s] | 2.000 | ||||||

| Operating temperature [°C] | -20 to +100 | ||||||

| Operating medium | HL - HLP DIN 51 524 part 1/2 | ||||||

| Max. medium temperature [°C] | 120 | ||||||

| Min. medium temperature [°C] | -40 | ||||||

| Max. ambient temperature [°C] | 80 | ||||||

| Min. ambient temperature [°C] | -40 | ||||||

| Max. admission pressure (intake side) [bar] | 2 bar absolute | ||||||

| Min. admission pressure (intake side) [bar] | 0.8 bar absolute (Start 0.6) | ||||||

| Weight appr. [kg] | 8.3 | 8.6 | 9.2 | 9.8 | 10.5 | 5.4 | 11.5 |

| Degree of filtration | Class 20/18/15 due to ISO 4406 | ||||||

| Life expectancy | not less than 1x 107 load cycles against peak operating pressure | ||||||

| Efficiency η vol: | 93 | 93 | 94 | 95 | 95 | 94 | 95 |

| Efficiency η hm: | 91 | 92 | 92 | 93 | 93 | 92 | 93 |

| Pump noise* (measured in sound chamber) dB[A] |

62 | 63 | 64 | 65 | 66 | 64 | 68 |

EIPC5 Series

Testing condition:n = 1.450 min-1,Δ p = 250 bar,T = 50 °C,Medium: HLP 46

| Rated Size | 064 | 080 | 100 |

|---|---|---|---|

| Spec. volume Vth [cm3/rev]*** | 65.3 | 80.4 | 100.5 |

| Continuous operating pressure [bar]** | 250 | ||

| Peak operating pressure [bar] max. 10 sec 15 % duty cycle** |

270 | ||

| Cut-in pressure peak [bar]** | 280 | ||

| Nominal speed [min-1] | 100 - 2.800 | 100 - 2.800 | 100 - 2.500 |

| Max. speed [min-1] | 3.000 | 3.000 | 3.000 |

| Operating viscosity [mm2/s] | 10 - 300 | ||

| Starting viscosity [mm2/s] | 2.000 | ||

| Operating temperature [°C] | -20 to +100 | ||

| Operating medium | HL - HLP DIN 51 524 part 1/2 | ||

| Max. medium temperature [°C] | 120 | ||

| Min. medium temperature [°C] | -40 | ||

| Max. ambient temperature [°C] | 80 | ||

| Min. ambient temperature [°C] | -40 | ||

| Max. admission pressure (intake side) [bar] | 2 bar absolute | ||

| Min. admission pressure (intake side) [bar] | 0.8 bar absolute (Start 0.6) | ||

| Weight appr. [kg] | 11.5 | 13.0 | 13.5 |

| Degree of filtration | Class 20/18/15 due to ISO 4406 | ||

| Life expectancy | not less than 1x 107 load cycles against peak operating pressure | ||

| Efficiency η vol: | 94 | 95 | 95 |

| Efficiency η hm: | 92 | 93 | 93 |

| Pump noise* (measured in sound chamber) dB[A] |

69 | 70 | 71 |

EIPC6 Series

Testing condition:n = 1.450 min-1,Δ p = 250 bar,T = 50 °C,Medium: HLP 46

| Rated Size | 125 | 160 | 200 | 250 |

|---|---|---|---|---|

| Spec. volume Vth [cm3/rev]*** | 125.7 | 160.1 | 200.9 | 249.9 |

| Continuous operating pressure [bar]** | 250 | 160 | 140 | |

| Peak operating pressure [bar] max. 10 sec 15 % duty cycle** |

280 | 170 | 150 | |

| Cut-in pressure peak [bar]** | 300 | 180 | 160 | |

| Nominal speed [min-1]**** | 400 - 2.500 | 400 - 2.000 | ||

| Max. speed [min-1] | 2.800 | 2.200 | ||

| Operating viscosity [mm2/s] | 10 - 300 | |||

| Starting viscosity [mm2/s] | 2.000 | |||

| Operating temperature [°C] | -20 to +100 | |||

| Operating medium | HL - HLP DIN 51 524 | |||

| Max. medium temperature [°C] | 80 | |||

| Min. medium temperature [°C] | -20 | |||

| Max. ambient temperature [°C] | 80 | |||

| Min. ambient temperature [°C] | -20 | |||

| Max. admission pressure (intake side) [bar] | 2 bar absolute | |||

| Min. admission pressure (intake side) [bar] | 0.8 bar absolute (Start 0.6) | |||

| Weight appr. [kg] | 27.5 | 30 | 43 | 54 |

| Degree of filtration | Class 20/18/15 due to ISO 4406 | |||

| Life expectancy | not less than 1x 107 load cycles against peak operating pressure | |||

| Efficiency η vol: | 94 | 94 | 93 | 93 |

| Efficiency η hm: | 90 | 91 | ||

| Pump noise* (measured in sound chamber) dB[A] |

76 | 77 | 77 | 78 |

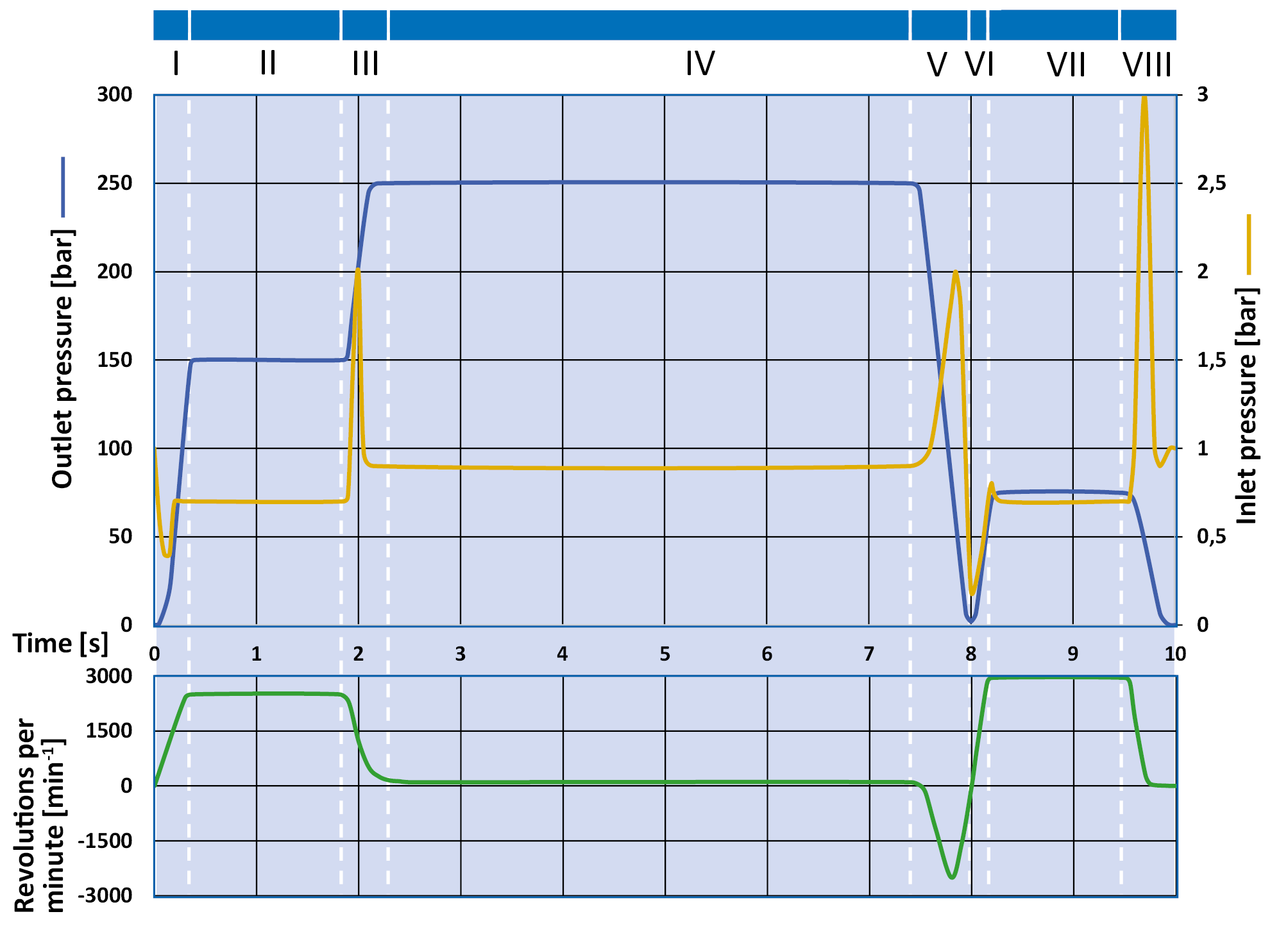

Variable-speed operation

As a matter of principle, Eckerle internal gear pumps are eminently suited for variable speed operation. Even at low viscosities and high temperatures of the pumping medium, the pumps run extremely energy efficiently and highly dynamically over a wide speed range due to the radical and axial gap compensation.However, with variable speed operation certain boundary conditions should be observed. The exemplary cycle shown below illustrates this clearly.

I. Start: Eckerle internal gear pumps able to build up pressure from standstill. This happens smoothly when the pump starts from an unpressurized state. Please talk to Eckerle, if due to the system design the pump is pressurized at standstill.

II. Pump Operation: Eckerle internal gear pumps are capable of providing a speed-dependent volumetric flow at any pressure level during pump operation. However, application limits of the respective sizes must be observed.

III. Deceleration: With Eckerle internal gear pumps very high decelerations can be achieved, it must be ensured though that line-dependent pressure peaks can develop within the suction side. These should not exceed the maximum permissible inlet pressure.

IV. Pressure Holding Operation: Eckerle internal gear pumps are able to build up high pressures even at very low speed due to the gap compensation, hold pressure operation is thus extremely energy-efficient. Pump operation should follow after the hold pressure operation to flush out the pump.

V. Reverse Operation: Eckerle internal gear pumps are usually able to run highly dynamically in the oppsite direction of rotation in order to lower pressure peaks, or by means of a hydraulic motor. However, it must be ensured that the output pressure is always higher than the input pressure.

VI. Acceleration: With Eckerle internal gear pumps very large speed-ups can be run. These are limited by inlet pressure, geometry of the suction line and viscosity. However, these may not drop below the specified minimum inlet pressure of the series.

* To avoid critical operating points, we recommend taking measurements of the pump’s inlet and outlet pressure near the pump with a scanning rate of at least 1 kHz when a new pump cycle starts.

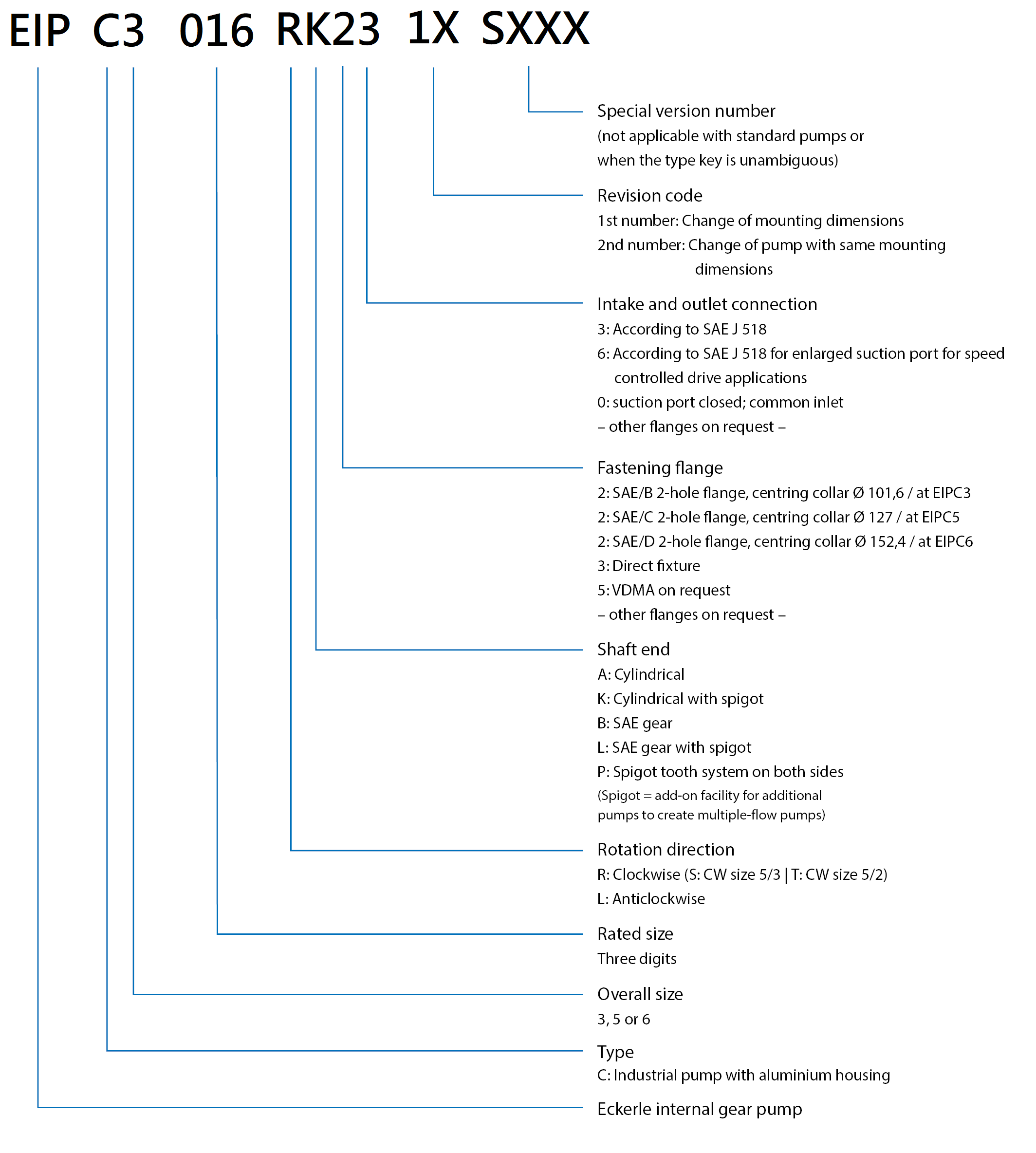

Model No.

EIPC3-RA23-1X,EIPC3-RB23-1X,EIPC3-RK23-1X,EIPC3-RK20-1X,EIPC3-RP30-1X,EIPC3-RK201X,EIPC5-RA23-1X,EIPC5-RB23-1X,EIPC6-RA23-1X,EIPC6-RB23-1X

- Code

-

Model Code

- Chart

-

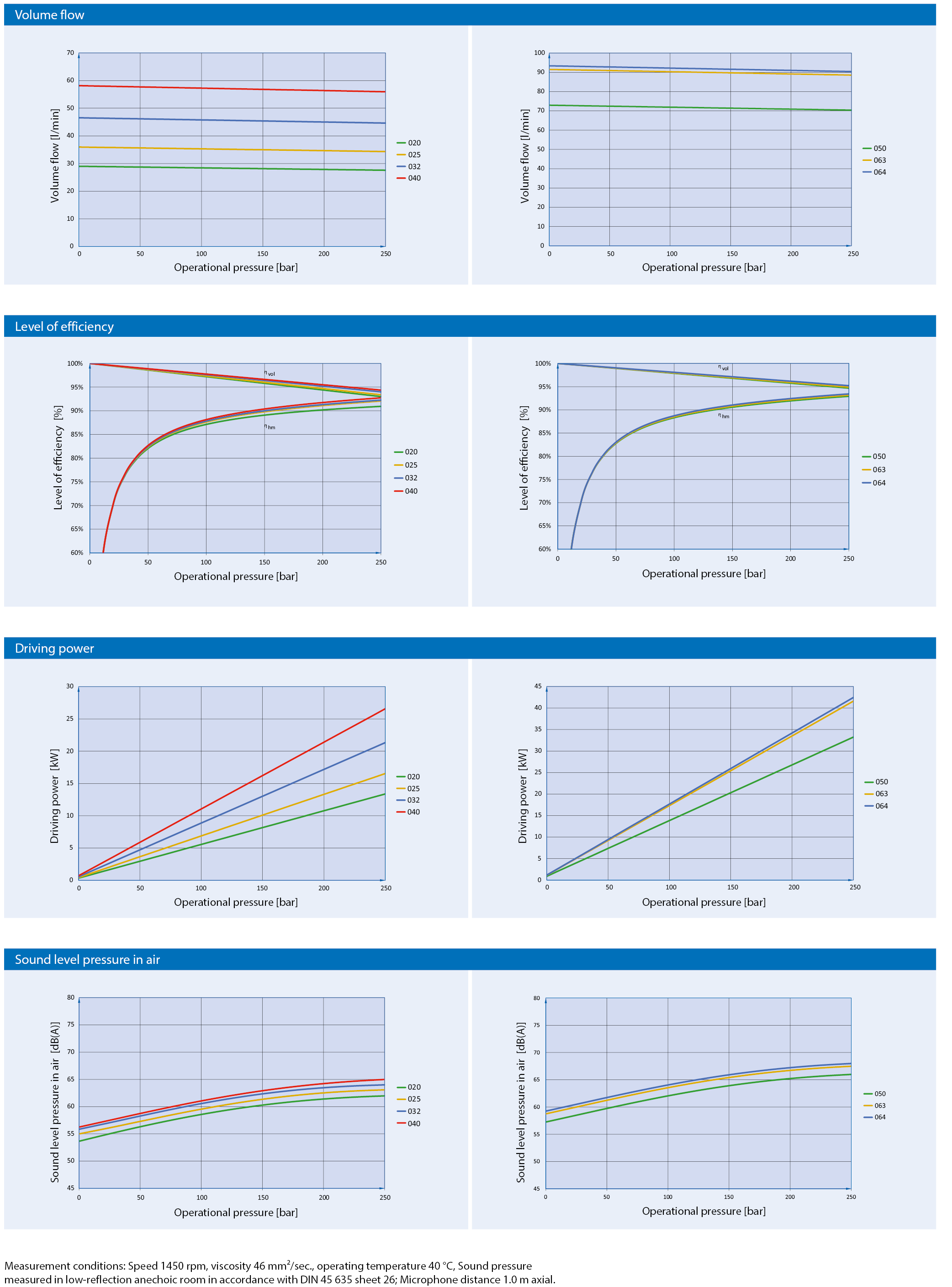

Performance Curve

EIPC3

Testing condition: n = 1.450 min-1,Δ p = 250 bar,T = 50 °C,Medium: HLP 46

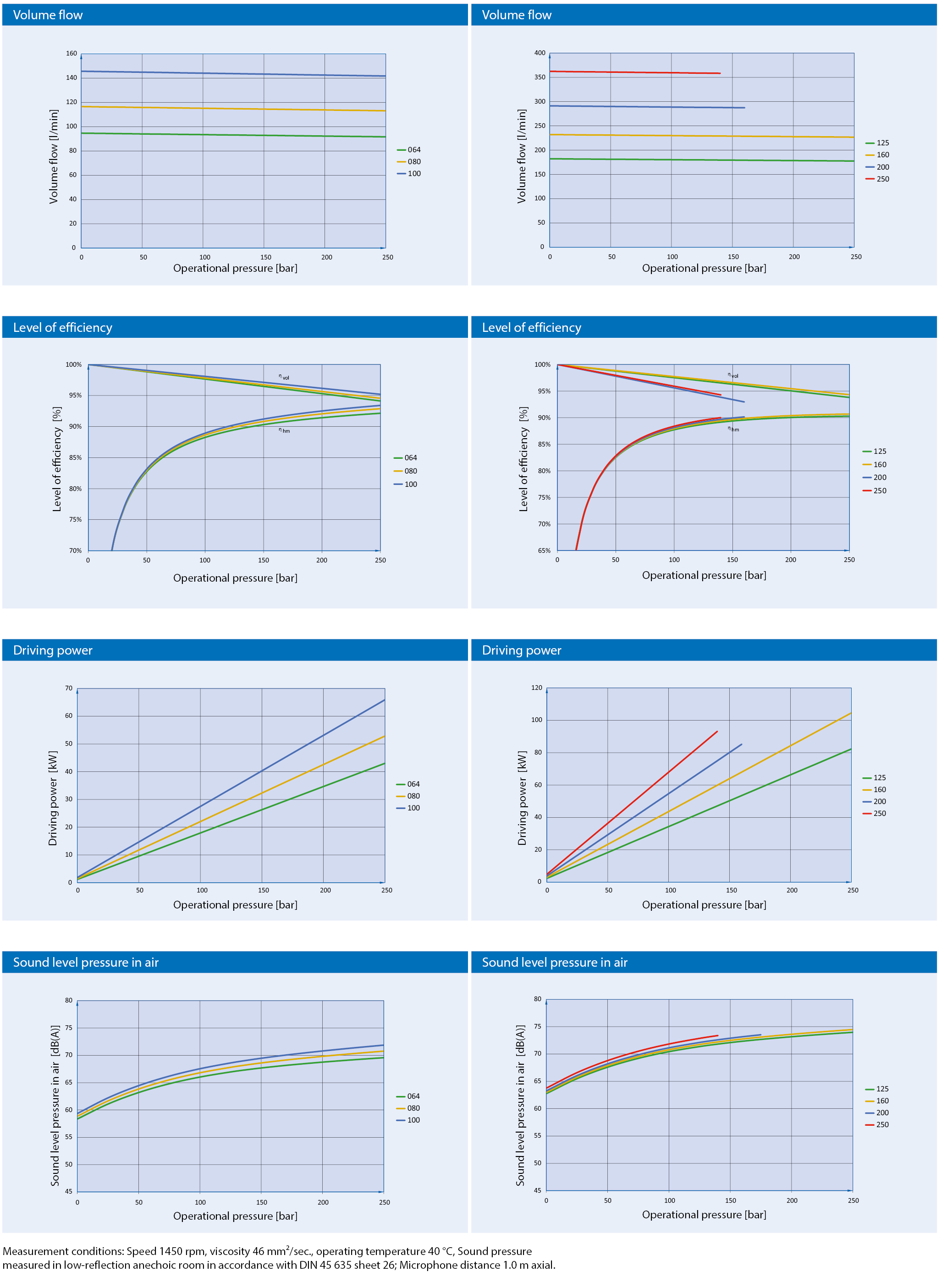

EIPC5.6

Testing condition: n = 1.450 min-1,Δ p = 250 bar,T = 50 °C,Medium: HLP 46

EIPC5.6

EIPC5.6

- DWG

-

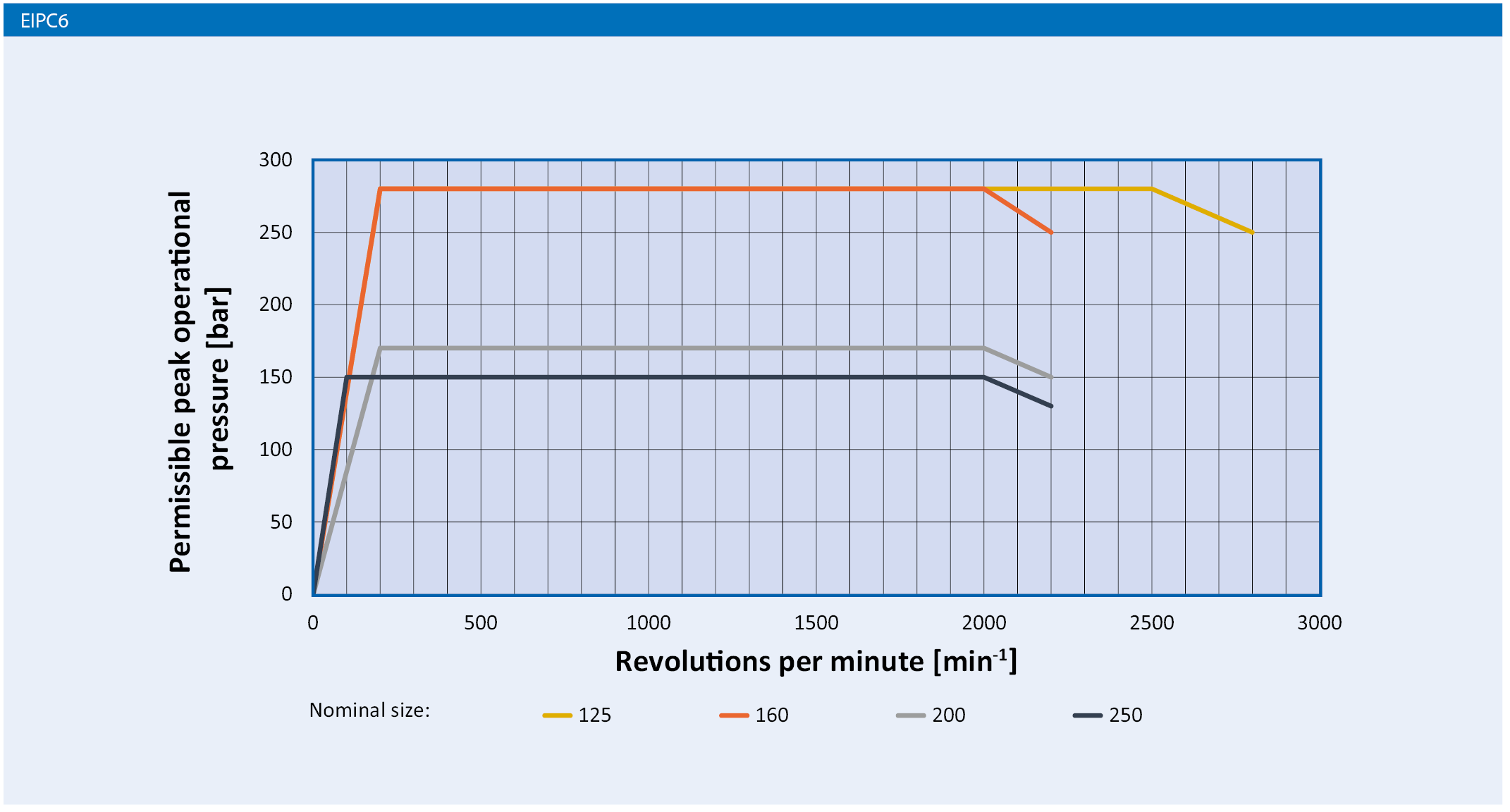

Measurement

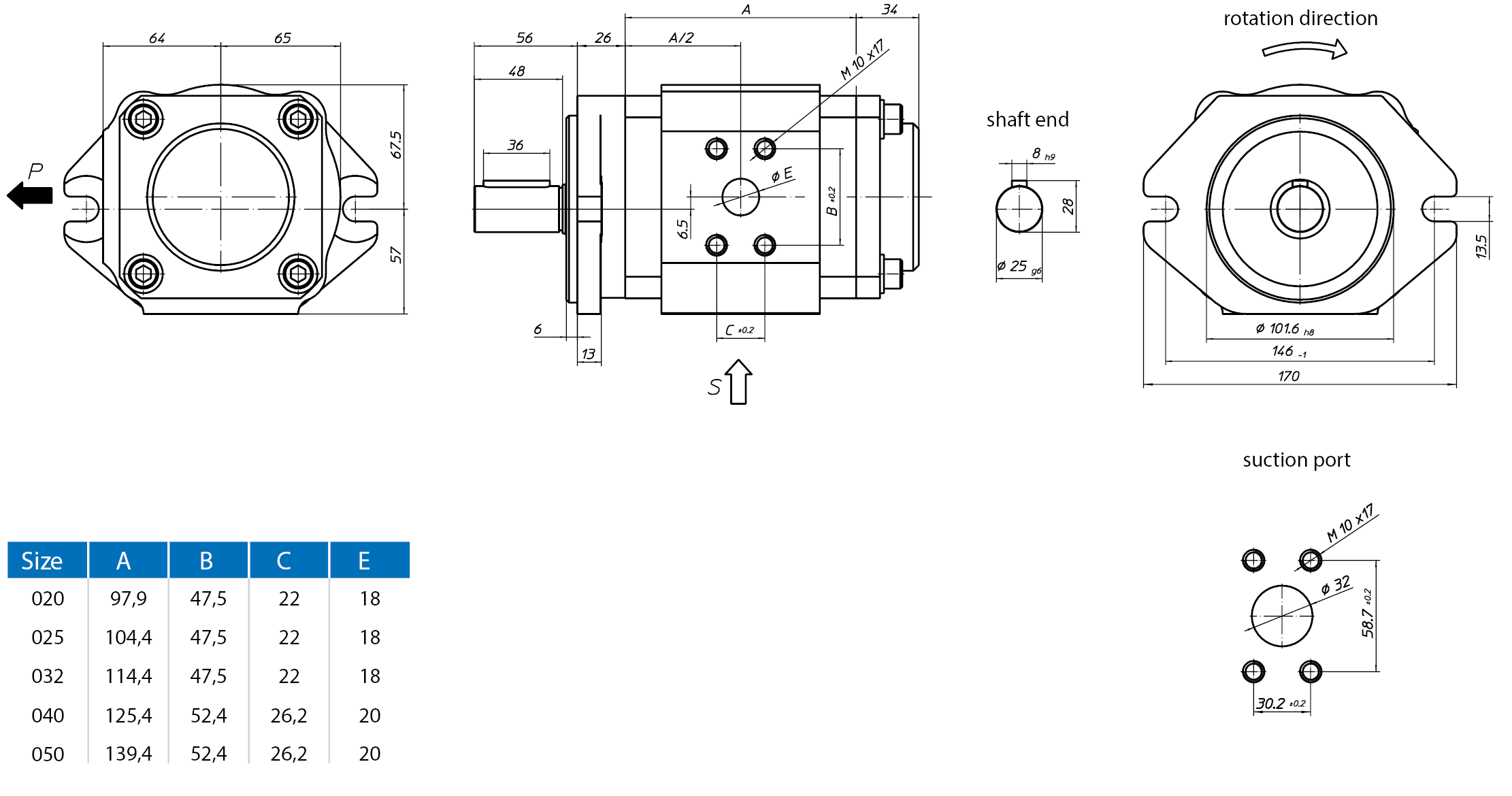

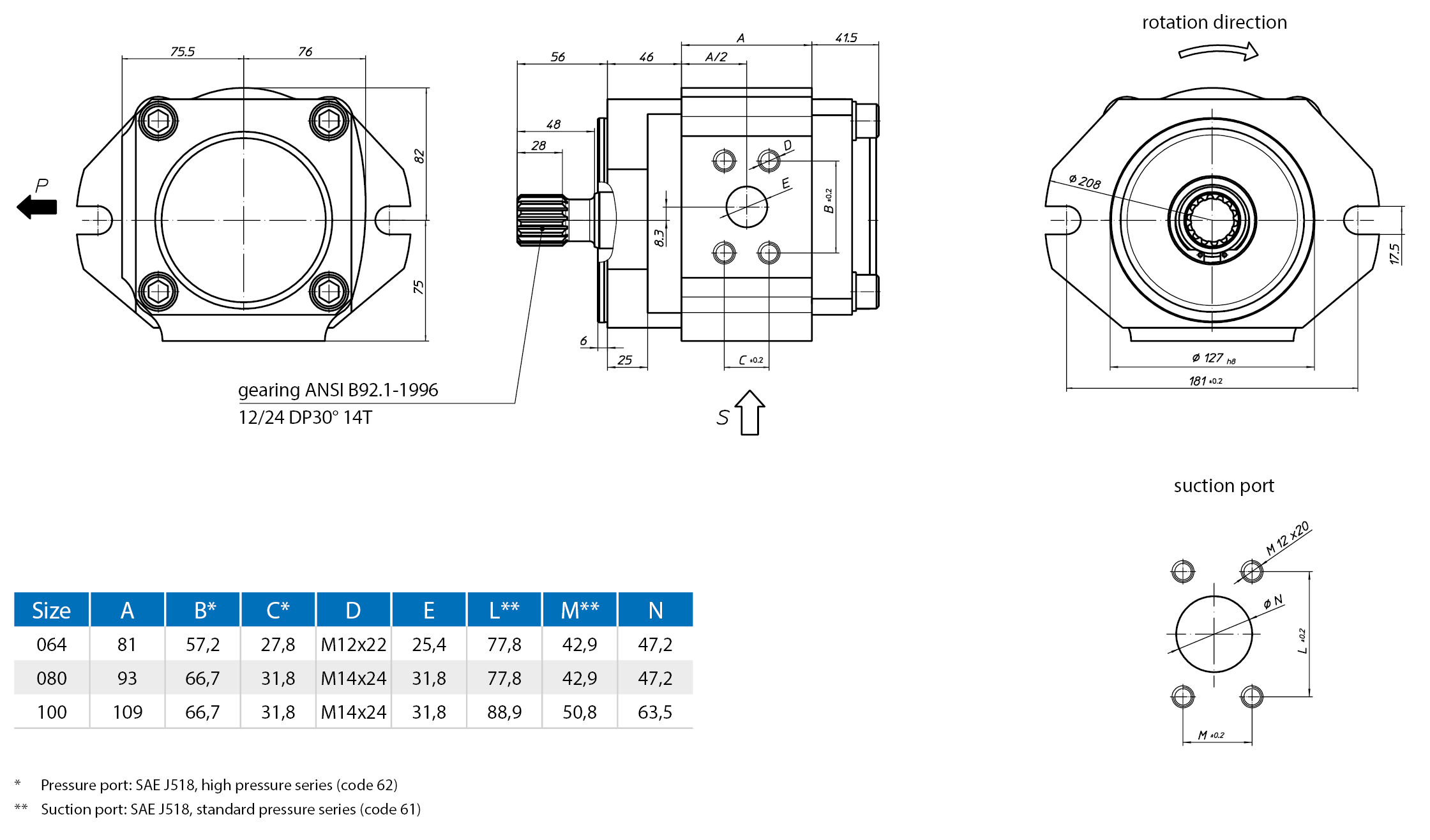

Pump with SAE-2-B-hole flange and cylindrical shaft

Order Example: EIPC3-RA23-1X

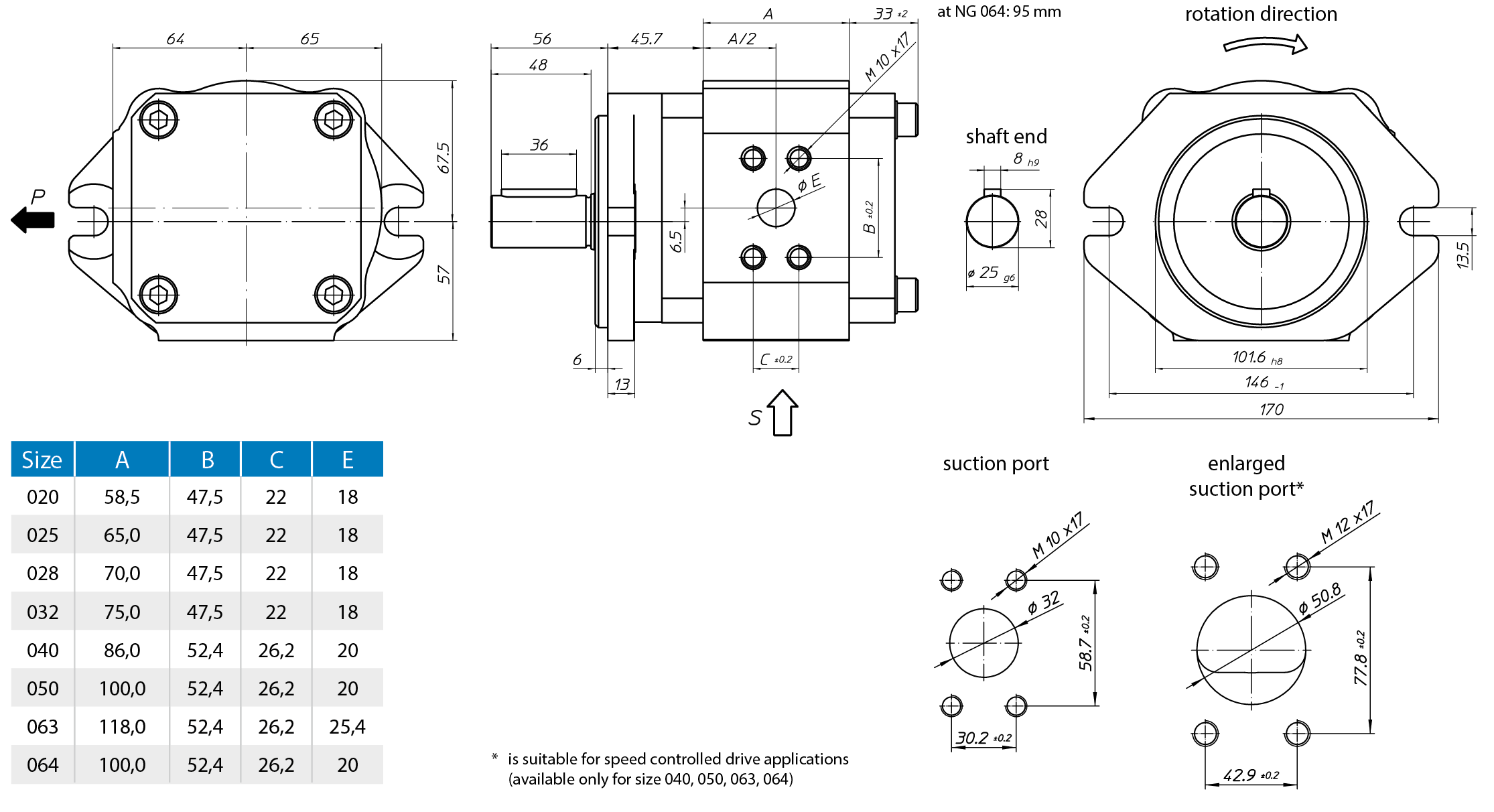

Pump with SAE-2-B-hole flange and spline shaft

Order Example: EIPC3-RB23-1X

Pump with SAE-B-2-hole flange and cylindrical shaft with PTO through drive option

Order Example: EIPC3-RK23-1X

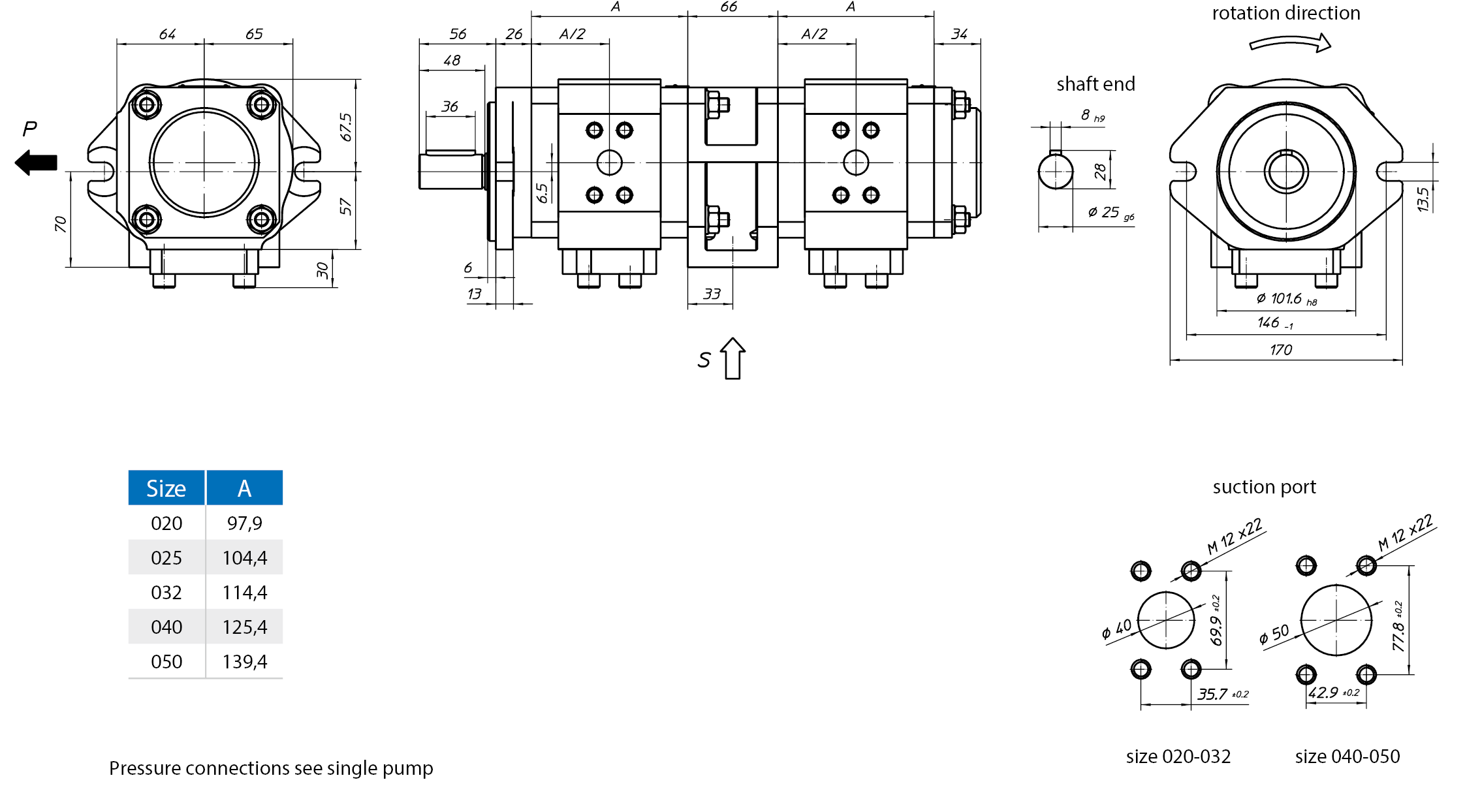

Double Pump with SAE-B-2-hole flange and cylindrical shaft

Order Example: EIPC3-RK20-1X+EIPC2-RP30-1X

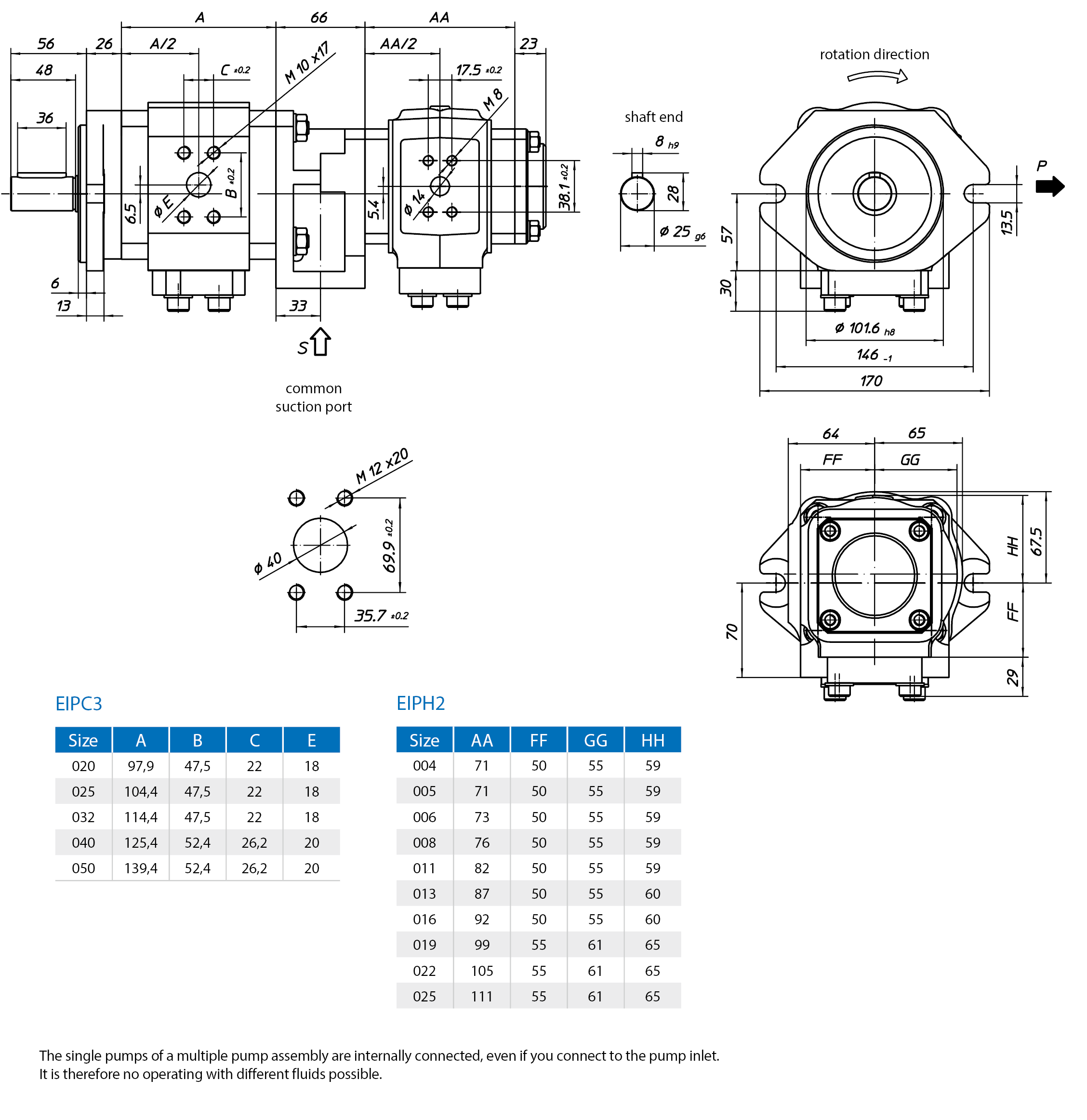

Double pump with SAE-B-2-hole flange and cylindrical shaft

Order Example: EIPC3-RK20-1X+EIPH2-RP30-1X

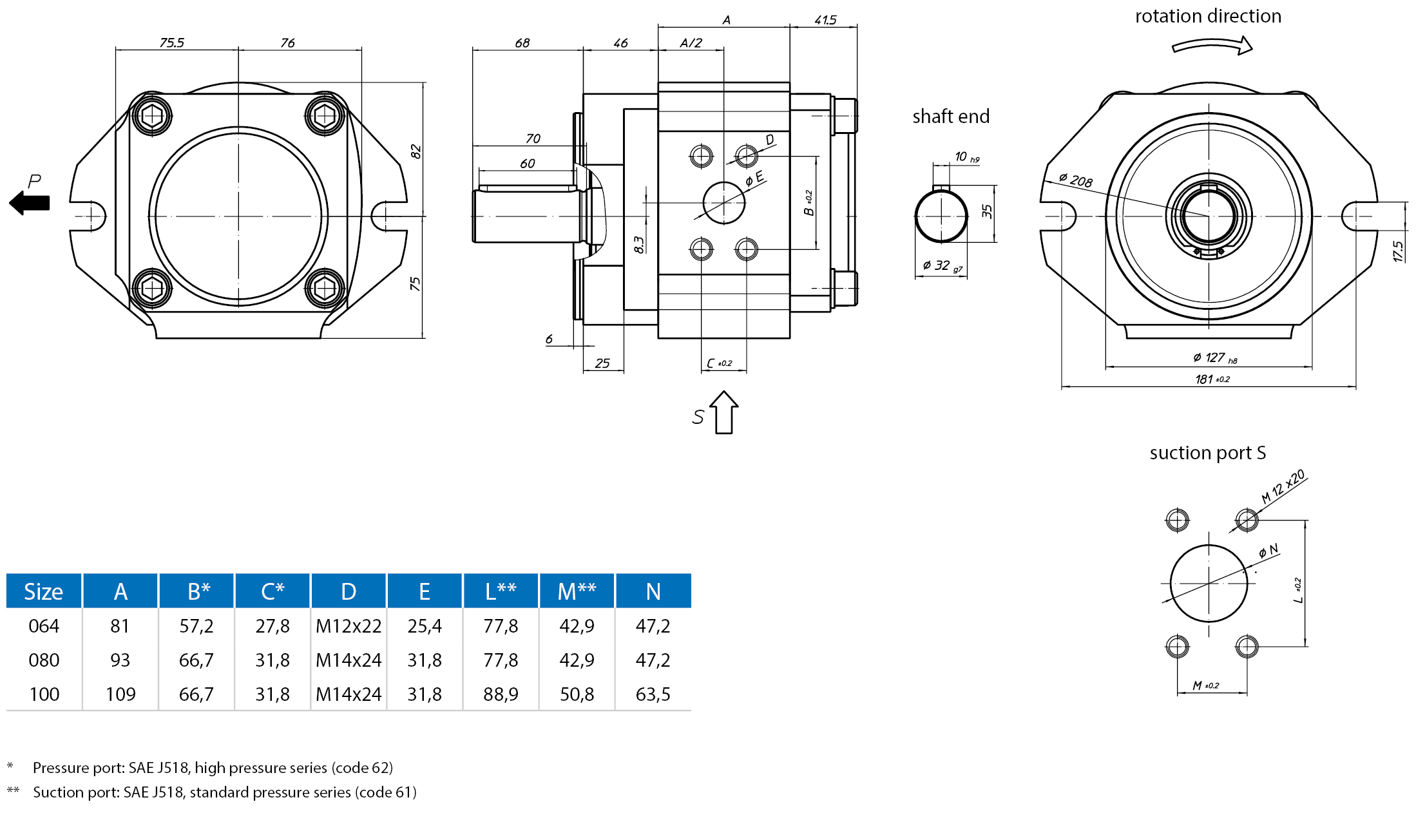

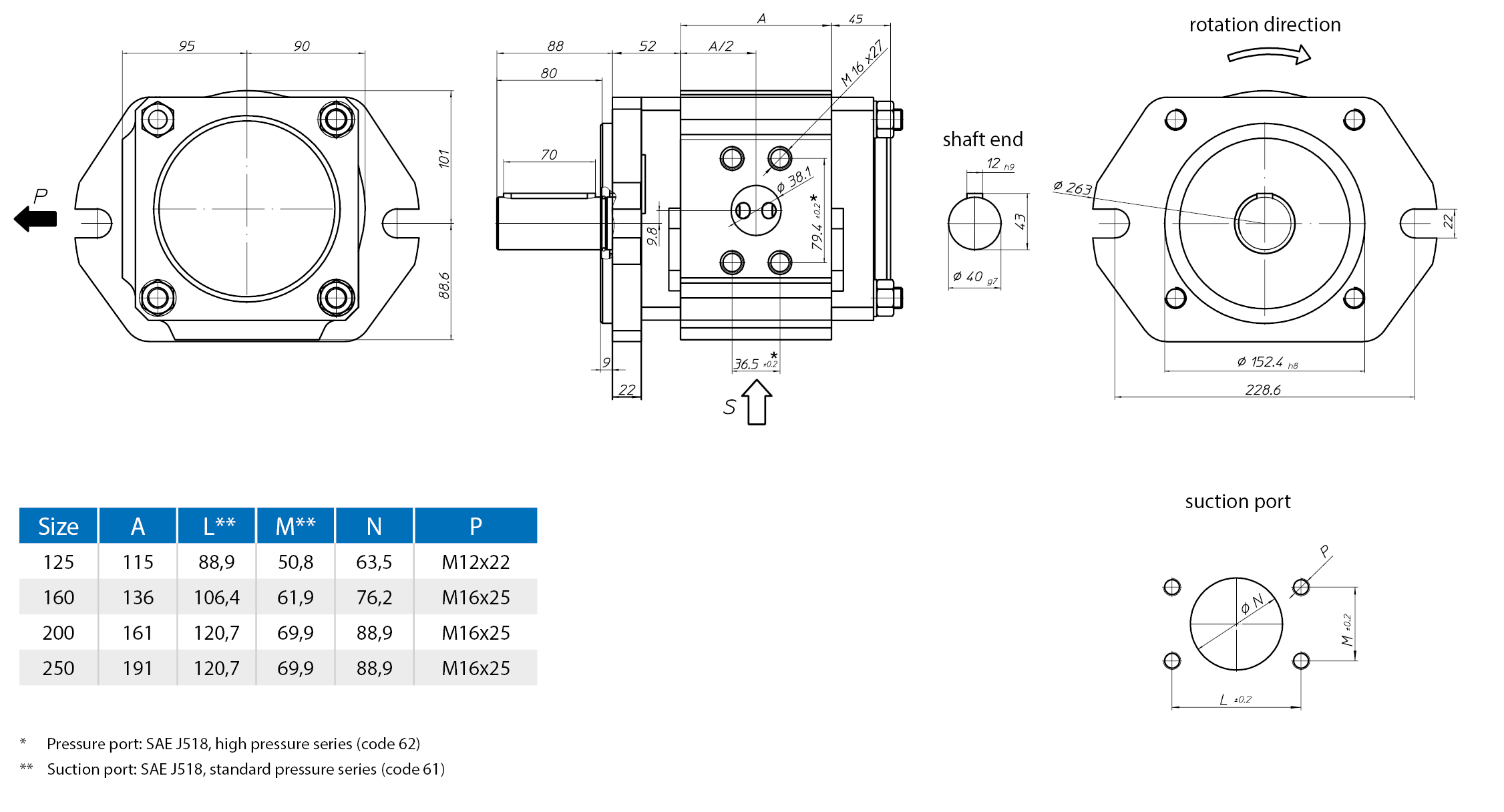

Pump with SAE-C-2-hole flange and cylindrical shaft

Order Example: EIPC5-RA23-1X

Pump with SAE-C-2-hole flange and spline shaft

Order Example: EIPC5-RB23-1X

Pump with SAE-D-2-hole flange and cylindrical shaft

Order Example: EIPC6-RA23-1X

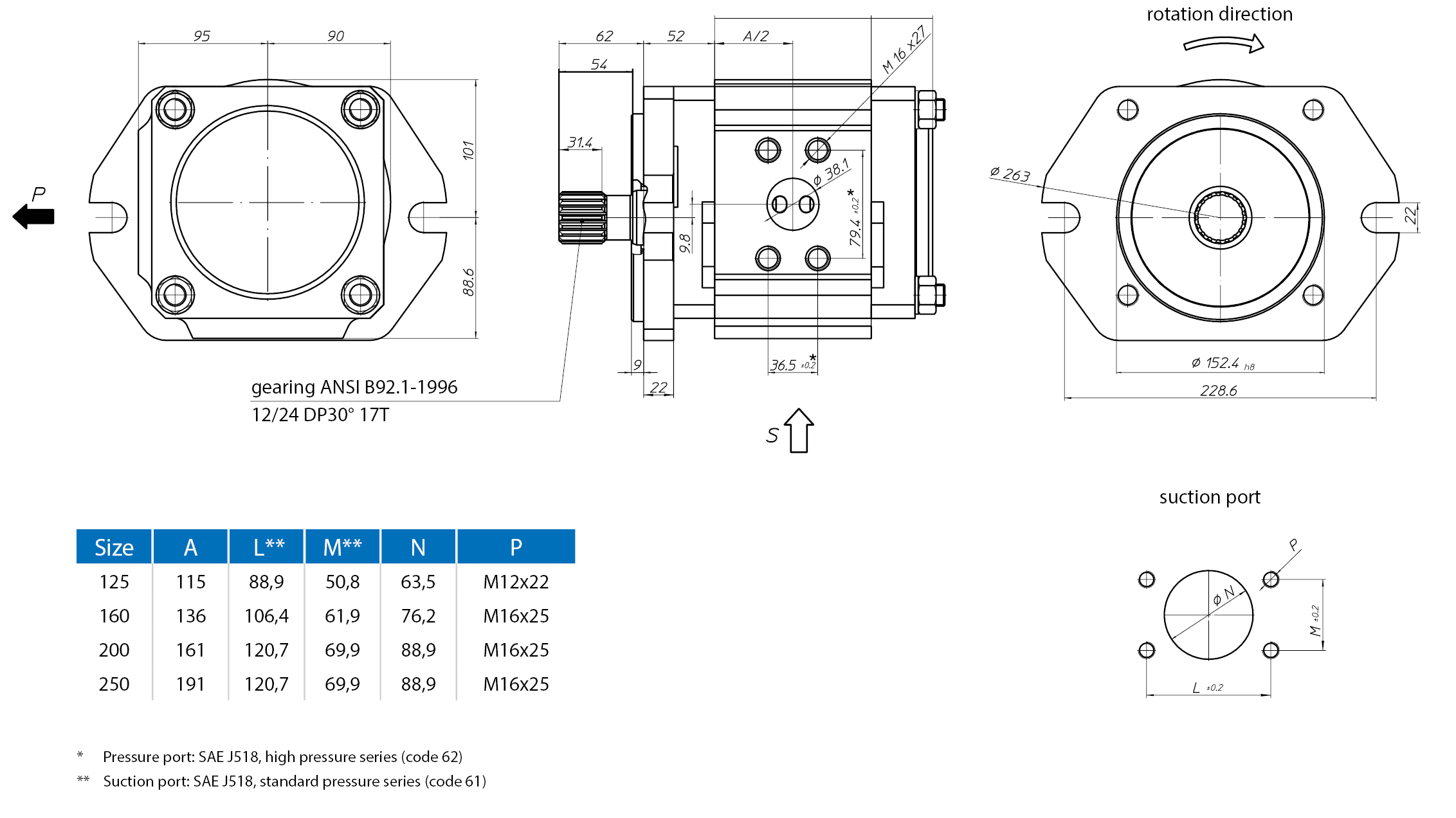

Pump with SAE-D-2-hole flange and spline shaft

Order Example: EIPC6-RB23-1X

CML, Camel Hydraulic, Camel Precision Eckerle Internal Gear Pump EIPC Service Introduction

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a Eckerle Internal Gear Pump EIPC supplier and manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Eckerle Internal Gear Pump EIPC production service, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

CML Brand Story

Enthusiasm catalyzes dreams; Energy promotes industry and drives continuous progress in the world.

Customer Service

With the rich product range, years of experience CML can provide integrated solutions to achieve customers' benefits.

Global Network

CML serving customers all over the world through local agents and prompt air and sea freight deliveries.